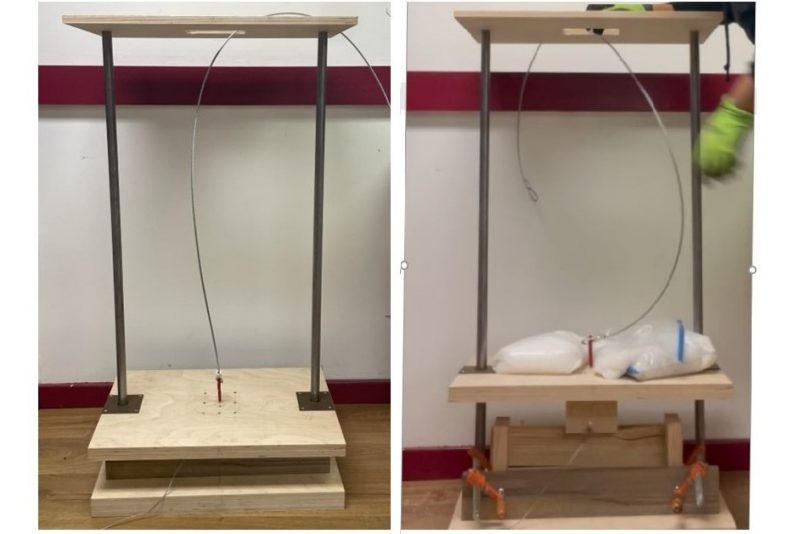

An initial prototype for a simplified method of testing pallet fasteners was designed by packaging student Alonda Johnson

To determine the strength of fasteners in joints on a pallet, it is generally necessary to conduct an incline impact test, which involves a pallet colliding into simulated forklift tines. While this method accurately predicts pallet performance, it is time-consuming and expensive. Individual fastener strength can be estimated by conducting a Fastener Quality Analysis (FQA), which includes a Morgan Impact Bend Angle Nail Test (MIBANT), and then using that data to mathematically predict the fastener’s performance. However, there is no existing testing methodology that can be used to evaluate the dynamic performance of individual pallet joints. The purpose of this study was to ideate a testing apparatus that could simplify testing the strength of the fasteners in pallet joints.