Pallet Testing Lab

A Look Inside the Lab...

If you have experienced excessive damage claims, high costs, or are contemplating the introduction of a new pallet design, this laboratory’s testing services will be a real benefit to you.

We offer the following wide range of testing services to our clients:

- Evaluation of the safe load capacity of the pallet under different loading and support conditions using ASTM and ISO standards.

- Evaluation of the durability of a pallet.

- Evaluation of the friction of pallet's surface.

- Evaluation of the transmissibility of a pallet.

- Evaluation of the strength and stiffness of pallet components and connections.

- Evaluation of the quality of pallet fasteners.

We are an independent, ISTA and NMFTA certified, testing laboratory, staffed by highly-skilled, certified technicians who can perform tests in accordance with ASTM, AIAG, TAPPI, ISO, and ISTA standards and customized application methods developed in our laboratory for and/or by our clients.

Learn more about the various tests performed in this lab below:

Various Pallet Tests:

The strength and stiffness of the pallet is dependent on the pallet support and loading condition conditions. Typical supports conditions include

- Warehouse floor stacking.

- Warehouse racking across length and width.

- Fork lift support across the length and width.

- Conveyor support.

While the load can be applied using a uniform, flexible airbag, rigid ISO bars or using the actual product. If the pallet is classified as a general purpose pallet, the load needs to be applied using either an airbag or rigid ISO beam. On the other hand if the pallet is classified as a specialty pallet, the actual product should be used to apply the load.

The durability of pallets determines how long the pallet will be in circulation before it needs to get repaired. Most damages to a pallet are caused by the forklift. Most common damages include broken lead deckboards and block or stringer damage.

Our customized incline impact tester uses simulated fork tines that can simulate the impacts from a forklift and quantitatively assess how a pallet can resist these impacts.

Two common tests are conducted: block and endboard impact test.

During palletized transportation, pallets act like springs thus based on the stiffness of their top deck the pallet can magnify the vibration produced by the trailer. This can results the packages carried by the pallet experiencing much more vibration and potentially experiencing damages. The transmissibility test can tall pallet designers the natural frequency of their pallet and the expected magnification factor.

The frictional performance of the pallet surfaces could be an indication of the pallet contribution of the unit load stability during transportation. Lower fiction the pallet top deck has more likely the packages will shift off the pallet during transportation. Our comprehensive pallet friction analysis can provide a detailed view on the friction between the top deck and boxes, friction between empty stacked pallets and friction between the forktines and the pallet.

Components tests evaluate the bending strength and stiffness of pallet parts including stringers, deckboards, and blocks. These properties can be used to predict the performance of a pallet.

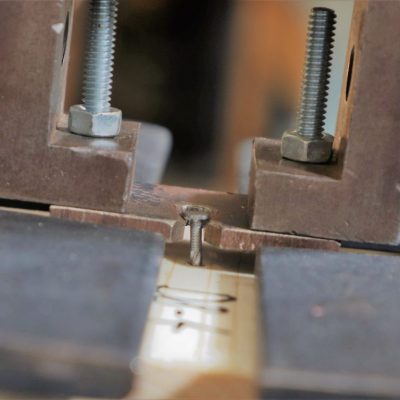

Evaluations of pallet fasteners allow companies to comply with regulations. Fastener tests include the Fastener Quality Analysis (FQA), which provides information about the effectiveness of the investigated fastener on the durability of the pallet. Fastener tests also provide information about compliance with ANSI Mh1. The FWI (Fastener Withdrawal Index) and FSI (Fastener Shear Index) are calculated as described in ASTM F680. Additional performance evaluations include actual withdrawal/shear/head pull through resistance of nailed joints. These tests follow ASTM D1761.