Research Highlight: Evaluation of six packaging designs for portable AC units to be shipped thru e-commerce channels

One of the world’s largest manufacturers of major home appliances sponsored an undergraduate research project for the students in our department for the fall semester 2022. Undergraduate student Matt Simonson (Junior, Franklin Lakes, NJ) and Mehr Ghotra (Senior) were selected to evaluate various packaging systems used to transport portable AC units thru e-commerce distribution channels. A final report was presented to the sponsor summarizing the findings and giving theoretical analysis of the packaging systems’ performances and recommended improvements to the packaging.

E-commerce is the market where goods and products are sold via the internet. Nearly anything can be bought through ecommerce today and that market is highly competitive. Ecommerce packaging is driving packaging engineers to develop new, sustainable solutions and more convenient ways of shipping products throughout the world. It also affects material use; packages that are shipped between multiple places need to withstand more hazards and be more protected while in transit. The responsibility of protective packaging has increased with the growth of ecommerce. Each characteristic is important to make sure products can be shipped worldwide while being protected to withstand risks. Engineers have had to increase the usage of protective packaging, like foam or corrugated materials, and even implement flexible packaging options just to comply and compete in a complex market and supply chain that is not as easy as typical retail.

For this investigation, the students evaluated six different models of portable air conditioners from six major brands. Each unit went through a performance test and analysis using the ISTA Amazon 6 Series testing sequence, which is a full testing protocol with general simulations used to test a package’s protection abilities. There are many different tests that all evaluate different aspects of a package’s strengths and protection capabilities. Examples include drop testing, compression testing, and vibration testing - all to simulate real-world situations that these packages could experience during distribution.

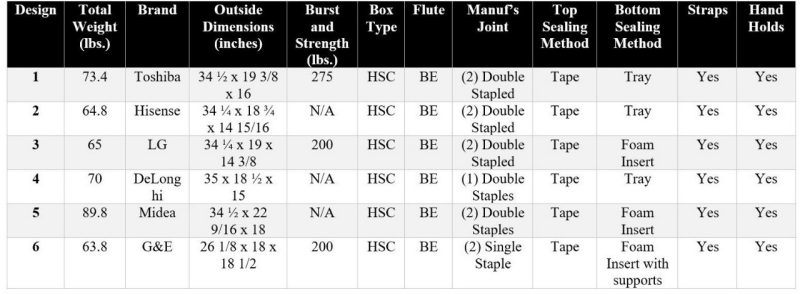

First, the AC units were broken down and parts-lists were created to detail the packaging specifications of each model (Table 1 and Image 3). When creating these Bills of Materials (BOM), our packaging students put the knowledge that they learned about the different packaging materials to the test. A quantitative assessment of the different types of materials used for the packaging solution is not just important in ensuring that the proper packaging is used, but it is also essential in determining the environmental performance of the packaging solution.

The ISTA Amazon testing processes gave the students substantial information about the portable AC units. They ran all six brands through the same test sequences, so they were able to compare and identify which units had stronger protection properties than others. They were able to see which units performed better in certain areas, and they came up with theoretical conclusions to determine which of the units had the best strength and protection abilities.

All of the packages were put thru a series of drop tests on each face and edge, vertical compression tests, and stacking compression tests. Then each package was subjected to four different vibration profile tests before again being drop-tested on its various faces/edges (Image 2). Once the units completed the ISTA 6B testing sequence, they were each broken down to inspect and assess any damage that could have occurred to the packaging materials and the unit itself through testing.

To assess the sustainability of the packaging solutions, the packaging materials used for each of the different designs were sorted and calculated to determine the percentage of curbside recyclable materials, percent of fiber-based materials, and also the package-to-product weight ratio as a percentage. Knowing all of this showed the researchers which designs were more sustainable and what could be improved as possible redesigns of any or all of the current packaging systems.

The project was a great opportunity for our students to practice package testing and creating packaging specifications. In addition, the project sponsor will be able to take this information and improve or alter their current packaging designs in order to compete with companies that might have stronger components in their portable AC packages.