Research Highlight: Undergraduate exploration of insulated shipping containers for cold chain

Image 1. Mark Brumnbaugh measuring a Home Chef meal kit box.

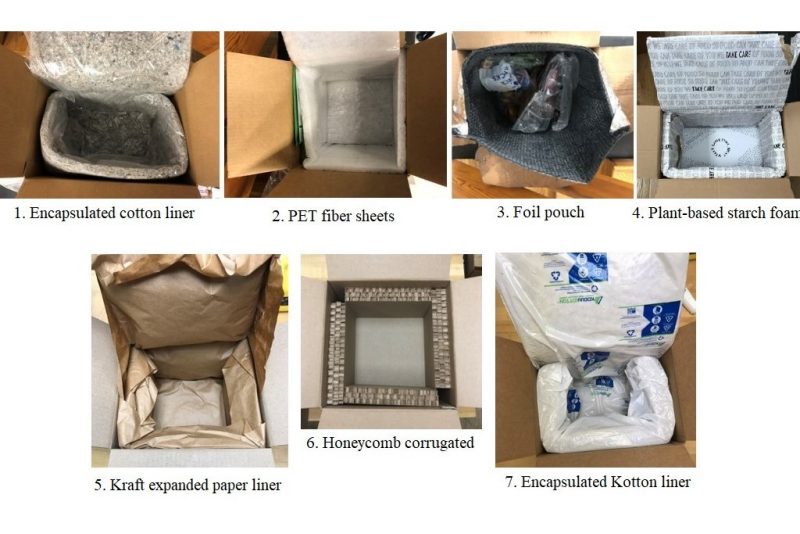

A partner company of CPULD recently sponsored a project for the undergraduate students in the Packaging Systems and Design major. The project was to investigate multiple major meal kit companies to assess their packaging in terms of effectiveness and sustainability. Mark Brumbaugh and Livvy Do were selected to research meal kits from Dinnerly, HomeChef, and Blue Apron, as well as meal kit specific packaging from Smurfit Kappa, Daily Harvest, PaperLiners, KodiaKotton. These particular kits and packaging were selected in order to provide a wide range of packaging/insulation types for this research project (Image 2).

Image 2. Types of insulation/packaging being evaluated for meal kit and packaging companies.

The students measured (Image 1) and recorded (Image 3) everything that belonged in the meal kits, then repacked it all with the applicable insulation/packaging combinations and included a datalogger, Easy Log-USB-2-LCD, in each box as well as cold packs to fill the remaining space in each box. The boxes were sealed with one strip of tape across major box flaps and monitored for 2-3 days or until fully equilibrated with room temperature. The testing procedures used were based on the ISTA 7D Temperature tests for transport which included preconditioning, testing in a moisture-controlled chamber, and constant temperature measuring. The average performances of three or four samples of each brand/packaging combination were recorded and analyzed for their temperature performance, weight and volume efficiency, and sustainability level.

Image 3. Livvy entering data from testing meal kits.

The various meal kits maintained their temperature under 5 degrees Celsius for 30.1-54.1 hours with an average 41.7 hours. The weight efficiency was found by dividing the total weight of the package by the weight of the insulation only – a lower percentage is a better rating as it means they needed less insulation weight to keep their meals at the desired temperature. The meal kits tested showed weight efficiency ratings of 33.3% to 71.4% with an average of 52.28%. The volume efficiency is a slightly different way of measuring basically the same thing. In this case, the volume of the insulation is divided by the volume of the container. For volume efficiency, a higher percentage is better, as it means the whole meal kit is more efficiently packed which means it will be less expensive to distribute. The meal kits tested ranged from 51.1%-97.3% with an average of 77.12%.

Sustainability is a major concern with most modern companies, and the packaging field is no different. The various types of packaging/insulation tested in this project were given a sustainability rating based on their recyclability and biodegradability. In this area, the foil liners used by the Blue Apron brand received the lowest sustainability score as their foil is neither recyclable nor biodegradable. The Smurfit Kappa and the PaperLiner brands received the highest ratings as their packaging/insulation combo is both recyclable and biodegradable.

| Solution: | Temperature Performance |

Weight Efficiency |

Volume Efficiency |

Sustainability | Ranking Total |

|---|---|---|---|---|---|

| Home Chef | 4 | 1 | 2 | 4 | 11 |

| Blue Apron | 2 | 2 | 1 | 7 | 12 |

| Daily Harvest | 3 | 4 | 4 | 3 | 14 |

| Dinnerly | 1 | 3 | 5 | 5 | 14 |

| Paper Liner | 5 | 5 | 7 | 1 | 18 |

| Thermobox | 6 | 6 | 6 | 1 | 19 |

| Kodiakotton | 7 | 7 | 3 | 5 | 22 |

Table 1. Overall ranking of the various packaging/insulation combinations tested.

All data was combined to create an overall ranking of all packaging/insulation combinations that were tested (Table 1). The best temperature-controlled meal kit was the Dinnerly brand (Image 4a) which stayed at 5 degrees Celsius for 54.1 hours. Dinnerly used encapsulated cotton liners and a polymer made from LDPE. The best meal kit, in terms of sustainability, was the Daily Harvest brand which used insulation made from paper and inflated plant-based starch which resembles Styrofoam but is 100% recyclable. However, the best ranking overall went to the Home Chef brand (Image 4b) which used PET fiber sheets and #1 plastic, both of which are recyclable and helped maintain temperatures while having good volume and weight scores.

Image 4a. Dinnerly brand, the best temperature-controlled meal kit in packaging.

Image 4b. HomeChef brand, the best overall scored meal kit in packaging.