Saewhan Kim presented for CPULD at national ISTA conference

Image 1. Saewhan presenting at ISTA

CPULD was proud to have graduate student, Saewhan Kim, present his research findings at the ISTA TransPack global industry conference and forum in 2022. This is ISTA’s signature, annual event where the packaging community comes together to tackle today’s challenges and shape the future of transport packaging.

Saewhan shared the findings of a research project that he led and oversaw during the 2021-2022 school year about a new type of sustainable, paper-based, stretch film that can be used for unit load stabilization. Although the properties of the usual plastic stretch film make it an excellent material to effectively stabilize unit loads, the fact it is derived from fossil fuels and difficulties in recycling plastic stretch film creates a significant environmental burden.

Due to environmental concerns and in order to try and reduce the effects on global warming, major companies are showcasing their commitment to sustainable packaging by looking into other unit load stabilizers. Recent developments in paper science have allowed for the creation of a stretchable paper that can be used as a more sustainable alternative to plastic stretch films. The goal of the current project was to investigate the applicability of this new paper wrap to stabilize a unit load of carbonated beverages.

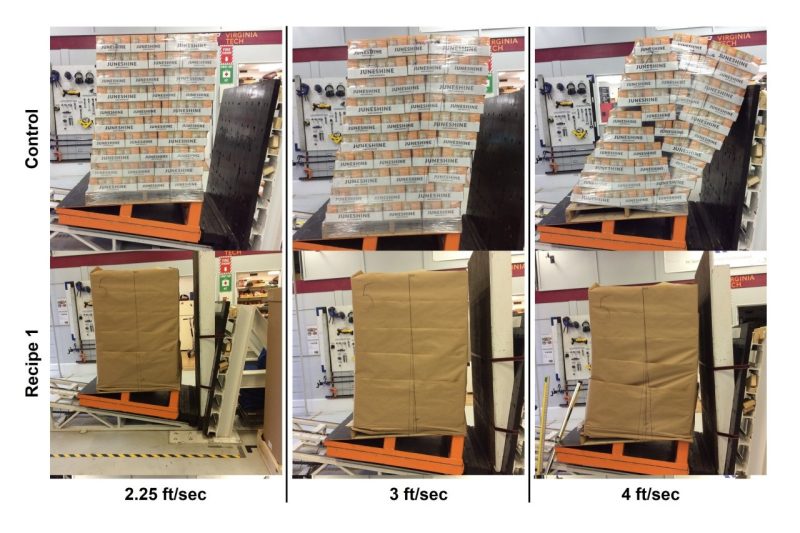

Saewhan’s series of experiments focused on the comparative testing of the unit load’s stability while contained by the two different wrapping materials: plastic LLDPE stretch film and a stretchable paper film. The unit load was wrapped with the paper film and then tested. The paper film was evaluated for its potential as a viable alternative to the also-tested, plastic-wrapped, control unit load. The total slip and sway were measured throughout the experiment.

The control unit load’s slip and sway increased with each impact until the plastic wrap failed to contain the unit load. Compared to that control unit load, the unit load wrapped with paper wrap, recipe 1 slipped 99% to 200% more. This was mainly due to the torn corners of the paper wrap at the point of contact with the pallet corners, which caused the paper’s failure to hold the unit load from slipping. However, the degree of product slip was not enough to affect the unit load stability since ample bottom-surface of the product was still sitting on the pallet. The slip results showed that paper wrap could be used on unit loads with a small underhang without film failure. On the other hand, the control unit load consistently experienced from 20% to 161% more sway than the paper wrap, recipe 1 unit load after each impact. Excessive sway on the control unit load led to unit load collapse, whereas the paper wrapped unit load remained stable after same speed impact.

Image 2. Plastic versus paper wrapped unit loads during incline impact tests.

In short, the paper wrapped unit load showed exceptional load stability performance. It was inevitable that a unit load would need to use more paper materials to get the same or better performance compared to plastic stretch film because paper wrap was not initially engineered for unit load stabilization purposes. It was found that paper wrap requires from 5.92 times to 8.55 times more material in terms of weight to reach the same or better stability performance on a unit load.

However, the new paper wrap can still be an effective alternative to plastic stretch film if the industry aims to eliminate fossil fuel-based materials from its supply chain since the paper wrap can provide superior performance for stabilizing unit loads. Many other load stabilizer options exist in the industry, but they are mostly fossil fuel-based products or unit loads need to meet specific circumstances to use them. In contrast, paper wrap could be widely applied to most unit load configurations with similar or better performance.