Research Highlight: Reusable Apparel Packaging in E-Commerce

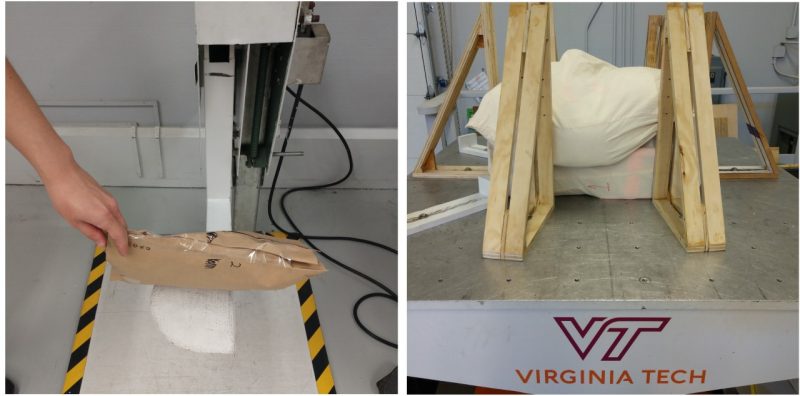

Image 1. A) Drop testing reusable packaging, and B) vibration testing of reusable packaging.

Today, many companies are trying to make their products and packaging systems more economical and environmentally friendly in response to a rapidly changing industry. There is currently a major market trend of using more sustainable and green packaging for commercial products. Reusable packaging can be described in many ways, each fitting different functions or end-of-life purposes. Packages can be reused by a consumer to find a new life for the package or can be taken to recycling and reusing centers. Packaging can also be reused within a business’ supply chain, shipping in special containers between their own warehouses and distribution centers.

This research project was conducted by Victoria Dashevsky, a senior from Alpharetta, Georgia, and Jordan Wells, a junior from Roanoke, Virginia, (Images 2 & 3) who are both undergraduates in Virginia Tech’s packaging systems and design program. Their goal was to research and present the current state of the reusable packaging market and then develop working proposals for their client, a major European clothing retailer who sponsored the study (referred to hereafter as the “Sponsor”), with suggestions on how to change some of their packaging to more sustainable solutions. First, they presented a literature review of the two main types of supply chain models that currently use forms of reusable packaging: business to business (B2B) and business to customer (B2C).

Image 2. Victoria Dashevsky

Image 3. Jordan Wells

Business to business (B2B) is a model of packaging logistics that involves items being shipped between or within a company’s infrastructure, including distribution centers, warehouses, stores, or other locations used in the operation of the business. Packaging systems used in B2B supply chains predominantly include reusable pallets, various forms of corrugated boxes, and reusable plastic containers. Reusable packaging is extremely common within B2B; there is no concern about enticing consumers to return the packaging. All of the materials stay within the company’s supply chain, which reduces expenses related to loss of packaging. There is also less of an initial investment since existing shipping routes are utilized. However, since reusable packages are often returned in batches to maintain shipping efficiency, they end up accumulating before being shipped back, presenting a safety hazard as well as taking up space. This leads to cases of idle inventory, and, in addition to safety and space concerns, hygiene is also a potential issue.

The alternative supply chain model is business to customer (B2C). These systems cover shipping to customers directly as opposed to between business locations. Most of the reusable packaging solutions in this market are for common consumer goods. Polybags, polymer sleeves, fabric totes, glass containers, metal containers, and plastic boxes are all common types of B2C reusable packaging. The packages can be viewed as a marketing asset. In fact, many reusable packages are designed with a secondary user function, such as a canvas tote. Proper sanitation and hygiene of the packages that are returned and reused must be ensured. Companies also need to incentivize the return of the packages, as people need some financial benefit to adjust. Two of the best ways that companies can incentivize returns is through deposits or purchase discounts.

A circular economy (CE) is routinely described as “closing the loop” of the supply chain. This is accomplished with the application of several main principles. First, waste and pollution are designed out of the process. Next, products and materials must be kept in use to avoid waste. Finally, natural systems must be regenerated in order to ensure future resource availability. These guiding statements shape what CE must be in the future and how the Sponsor’s goals can match them.

In the case of the Sponsor, the products that they ship are considered fast moving consumer goods (FMCG), which presents its own set of challenges to the company. All segments of the supply chain must be efficient and well-designed with CE principles in mind for new solutions to be effective. To make CE much more attainable for e-commerce packaging systems, a model called reverse logistics needs to be implemented. Reverse logistics deals with the recollection, preparation, modification, and ultimate repurposing of already used economic outputs.

Given the data collected about both the industry trends in reusable packaging markets and the examples of existing systems, four potential reusable packaging systems were presented to the Sponsor. Each option was chosen and then examined in lab tests to determine its efficacy. In considering the potential choices, previous successes of these solutions, the marketability/uniqueness of each, and how well they match the Sponsor’s stated sustainability principles were all taken into account.

- Solution 1: Returnable Polymer Pouch. In this option, the apparel is shipped to the consumer in a durable polymer pouch, which can then be folded up, placed in a mailbox, and returned back to the company. Once returned, the sponsor can repack the polymer pouch and ship it to another consumer.

- Solution 2: Recycled Fabric Waste Bag. This solution involves using fabric waste from the clothing production process or extra stock clothing items to make a bag to ship the clothing or products in. This bag can then be reused by the consumer for any purpose that they want.

- Solution 3: Hyper-recyclable Paperboard Pouch/Container. One of the sponsor’s principles for sustainability is using both recycled and recyclable materials. This option, a paperboard pouch, is recyclable instead of reusable. Being light, inexpensive, and easily disposable, this solution creates waste that isn’t harmful to the environment like discarded plastic film is.

- Solution 4: Heavy Corrugated Box or Plastic Corrugated Box. These solutions are commonly used in a B2B environment; however, their introduction into the B2C environment could generate significant environmental benefits but also comes with challenges.

After getting feedback from the sponsor, the students identified five package solutions (Image 4) for further evaluation: a single-use, apparel polybag; a single-use, apparel paper bag; a standard, corrugated box (determined by Amazon overbox standards); an Orbis, corrugated box; and a RePack, sample bag.

Image 4. Currently existing packaging options from the Sponsor and its competitors: (A) apparel poly bag, (B) apparel paper bag, (C) standard corrugated box, (D) Orbis corrugated box, (E) RePack sample bag.

To determine the ability of the packaging solutions to protect the products throughout the physical distribution, an ISTA 3A testing sequence was then conducted on all five packaging solutions (Image 1). The packages were filled with four products: two T-shirts, one pair of shoes, and a container of lip gloss. Due to the small size and weight of these products, the polybag, paper bag, and the RePack solutions were all categorized as “small” packages while the Orbis box and the standard corrugated box were categorized as “standard” packages. The durability test results were conclusive and clear; all sample packages went through all tests without any failures.

To determine the difference in the environmental performance of the different solutions, a graduate student group is working on a comprehensive Life Cycle Analysis.