Three graduate student research papers accepted for the IAPRI 2021 conference

Image 1. International Association of Packaging Research Institutes (IAPRI) conference banner

Like most conferences during this pandemic, the 30th annual International Association of Packaging Research Institutes (IAPRI) conference is being held virtually in June 2021. Established in 1971, IAPRI is a “unique global network which allows organizations to communicate and develop ideas, exchange experiences and in many cases reduce duplication of effort.” CPULD is a longstanding member of IAPRI and is one of its 90-member research/educational institutions from 31 different countries.

This year, three of our graduate students have had their research accepted by IAPRI. Their papers, summarized below, will be a part of the conference in June. This is a great opportunity for our students to network and learn about the latest research projects, as IAPRI conferences bring together the best packaging researchers around the globe.

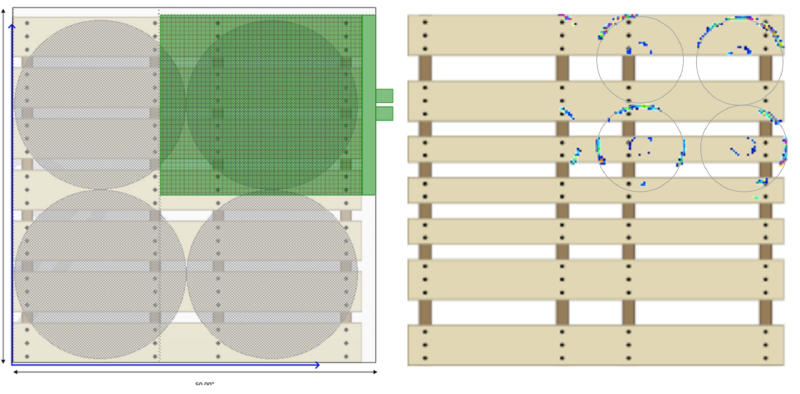

Doctoral student Mary Paz Alvarez’s paper is “The effect of plastic pails on pallet deflection and pressure distribution for stringer class wooden pallets.” Her research found that pallet deflection significantly decreases when pallets are loaded with pails compared to a flexible airbag. The reduction ranged from 32% to 89% for most pallet designs. Her findings indicate that pallets supporting unit loads of pails (Image 2A & 2B) will deflect significantly less than what they are currently designed for, and this reduced deflection could increase the load capacity of some pallet designs. Overall, these results reveal that wooden pallets should be designed for the specific type of packages they will be carrying in order to optimize the cost of the pallet and reduce the amount of raw materials used to manufacture wooden pallets.

Image 2. A) Pressure map setup for one quarter of pallet and B) pressure map reading for plastic pails.

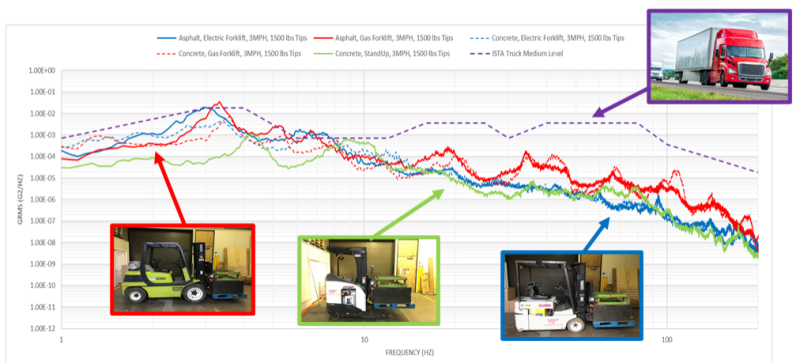

Master’s student Yu Yang Huang’s project was an “Investigation into the effects of various factors on the vibration levels experienced by unit loads under forklift handling conditions.” The goal of the first phase of Huang’s research was to understand how the vibration experienced by unit loads while being transported on forklifts is affected by speed, road conditions, unit load weight, forklift type, and sensor location. In short, his results showed that an increase in forklift speed increases vibration intensity. It was also discovered that forklifts on asphalt experienced a higher level of vibration compared to forklifts on concrete. On the other hand, an increase in the forklift load weight decreases vibration intensity. Among the three forklifts studied (gas-powered, electric-powered, and a reach truck), the gas-powered forklift has the highest Grms (root-mean-square) values on an asphalt road surface. Finally, he found that ISTA trailer trucks experience higher vibration levels than any of the forklifts (Image 3).

Image 3. Comparison between ISTA truck and forklifts in vibration levels experienced.

Master’s student Saewhan Kim’s project is “Characterizing the environmental impacts of common e-commerce packaging options for sustainability-minded stakeholders.” The goal of this study was to conduct a quantitative analysis of environmental impacts of popular e-commerce packaging options. Employing a life cycle assessment (LCA) method, the study compared the impacts of three e-commerce apparel packaging scenarios commonly used for distribution into the U.S. market: a corrugated board box, a virgin paper envelope, and a recycled-content, low-density, polyethylene (rLDPE) bag. When all three packaging scenarios are compared, it is clear that the corrugated board box e-commerce package scenario results in the highest environmental burdens across the greatest number of impact categories (Image 4). Although paper is generally perceived to be an environmentally preferable material to plastics, the rLDPE bag resulted in a lower environmental burden. Kim concludes that future work is needed to explore the implications of varied package weights and percentage of recycled-content adjustments to balance package performance and environmental impacts of the package within the e-commerce system.

Image 4. Comparison of the relative environmental impacts generated by the corrugated board box, the virgin paper envelope, and the rLDPE bag. (For each impact category, the package scenario yielding the greatest impact was set to 100% to demonstrate relative impact reduction made possible via the alternative package options.)