Research Highlight: Evaluating the effect of pallet deckboard gaps and overhang on the compression strength of plastic pails

Image 1. Rosa Williams conducting compression testing of a plastic pail on the Lansmont Squeezer.

The objective of this undergraduate research project, conducted during the fall 2020 semester, was to measure and analyze the effect of varying sizes of pallet deckboard gaps and pallet overhang gaps on the compression strength of three different sizes of plastic pails, assuming completely rigid deckboards.

Three undergraduate students participated in this research project: Jon Porter, a senior from Chesapeake, Virginia; Carter Engvall, a senior from Alexandria, Virginia; and Rosa Williams, a freshman from Marietta, Georgia. The project was sponsored by the National Wooden Pallet and Container Association through their industrial affiliate membership. The students investigated three different sizes of pails: 3.5-gallon, 5-gallon, and 7-gallon (all had a bottom diameter of 10.5 in.). They conducted the study using ASTM D642 guidelines and a Lansmont Squeezer Fixed Platen Compression Tester (Image 1).

Pails are an essential part of modern packaging and are used for a variety of fluids, ranging from chemical coatings and paints to juices and other food products. Despite their many uses, there has been little to no research done on the compression strength of pails within the context of palletization. As pails are a common form of packaging, understanding this complex relationship will greatly benefit the packaging industry. The general objective of this research project was to better understand the effect that pallet deckboard gaps and overhang have on three different sizes of plastic pails.

To simulate the effect of rigid deckboards with gaps and overhang, the pails were supported on a 5.5 in. wide a pallet deckboard simulator made of 0.75 in. plywood (Image 2). The deckboard simulators were positioned to create three different sizes of gaps and two sizes of overhang. The gaps were centered under the pails. To simulate the load distribution observed for stacked pails, a circular jig made of a bottom section of a pail reinforced with plywood was developed and used for the load application.

The guidelines of ASTM D642 (202) were used for the experiment that was conducted in order to find the compression strength of the pails being evaluated.

Image 2. Experimental setup for compression strength of a plastic pail on a 2.5 in. pallet gap.

The results revealed that the pail was the strongest on the support with no deckboard gap (control) and this support condition was significantly different from the rest of the support types. When the pail was supported on deckboards with varying sizes of gaps, the strength of the pails decreased by 1% to 30% depending on the design. However, the statistical analysis revealed that the pails’ strength measured for the different deckboard gap scenarios were not significantly different from each other. The support condition where the pail was overhanging the deckboard resulted the lowest pail strength values, reducing the pail strength between 12% and 46%. Contrary to the effect of deckboard gaps, there was a significant difference between the pail strength values observed for the different overhang scenarios. The pail strength decreased significantly when the overhang increased.

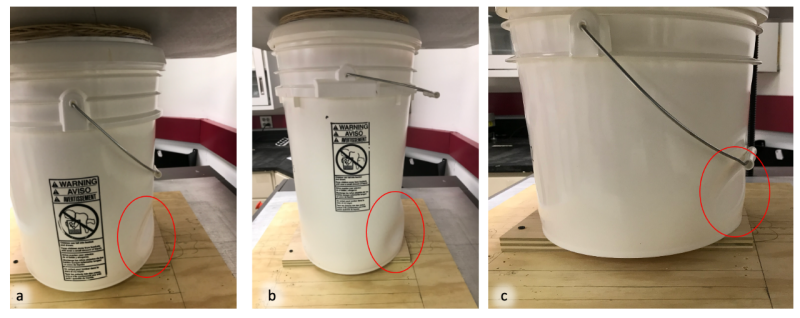

Image 3. Pail failure mode: sidewall buckling of the three sizes of pails tested.

The most common pail failure mode seen during testing was sidewall buckling (Image 3), while lid failure was observed for only a limited number of samples and designs. Sidewall buckling was present on all sizes of pails; lid failure was only present on the 3.5- and 7-gallon pails.

Based on the findings of this research project, it is recommended to avoid overhang, as it causes a much greater reduction in pail compression strength. While deckboard gaps reduce strength as well, the reduction in compression strength due to overhang is much more severe.