Research Highlight: Characterizing the environmental impact of common e-commerce packaging options for sustainability-minded stakeholders

Image 1. Image 1. Package transportation around the world for corrugated boxes, virgin paper envelopes, and rLDPE bags.

Electronic commerce (e-commerce), defined as an application of electronic means and technologies to conduct commerce, is a method of retailing that is currently drawing huge attention. Since the internet has become ubiquitous, e-commerce continues to grow and expand its influence at a remarkable pace. In the U.S., e-commerce sales have been growing at a rate of 28% annually for over 20 years. This is significantly different from traditional retail sales, which only grew 3% per year.

As such, there is increasing research focused on assessing and mitigating the environmental impacts of e-commerce packaging across a range of impact areas: energy consumption, greenhouse gas (GHG) emissions, waste generation, and comprehensive areas of environmental performance, including global warming potential, abiotic depletion, acidification, eutrophication, ozone depletion, freshwater and marine aquatic ecotoxicity, human toxicity, terrestrial ecotoxicity, and photochemical ozone creation potential. The acceleration of the concept of a “circular economy” around the world is also prompting research and interest in the role of packaging in the transition to more circular material production and consumption systems.

Apparel is one of the most common products sold within e-commerce systems. The apparel industry accounts for the largest share of e-commerce sales in the U.S.: 18% in 2015, totaling $52.1 billion. Hence, the need for e-commerce packaging in the apparel industry has also continued to increase. As e-commerce packaging waste and its impact on the environment continue to attract attention, several major multinational brands are working to transform their packaging systems to be more sustainable and environmentally conscious.

Master’s student Saewhan Kim (Image 2) has worked with circular economy expert Dr. Jennifer Russell of Virginia Tech’s Department of Sustainable Biomaterials to investigate the sustainability of different packaging solutions used by a European apparel company.

Image 2. Master’s student Saewhan Kim

Employing a life cycle assessment (LCA) method, this research study compared the environmental impacts of three different e-commerce apparel packaging systems commonly used for distribution into U.S. market: a corrugated board box, a virgin paper envelope, and a recycled-content, low-density, polyethylene (rLDPE) bag. LCA methodology examines the potential environmental impacts and risks of the product or system by evaluating input and output data throughout its entire life cycle. This research complied with ISO 14040-44 standards 27-31, which require compliance in four main steps: (1) goal and scope definition; (2) life cycle inventory (LCI) analysis; (3) life cycle impact analysis (LCIA); and (4) interpretation. The life cycle impacts of the three apparel e-commerce packaging options were assessed and their relative environmental impacts compared.

Basically, this project involved conducting a quantitative analysis of environmental impacts of popular e-commerce packaging options and then informing decision-makers, consumers, and retailers of the objective comparisons of the environmental burdens generated by the various e-commerce apparel packaging systems. A “cradle-to-grave” perspective, including raw material extraction, packaging manufacturing, transportation processes, and end-of-life scenarios, was applied to this study.

In accordance with the requirements of our collaborating European multinational apparel company (hereafter identified as “industry collaborator”), the studied scenarios assumed that package input materials (corrugated board, virgin paper, and rLDPE) were sourced and manufactured in Europe (Sweden and Spain) and then shipped into the U.S. e-commerce marketplace. Thus, two geographical scopes were selected in this study: Europe (Sweden and Spain) for the raw material extraction and packaging manufacturing and the U.S. for post-manufacturing processes.

The life cycle for each packaging scenario was separated into four different stages and individually assessed to evaluate each stage across different environmental impact categories. The first stage of the life cycle was raw material production, which included the logging process for paper-based packaging scenarios and plastic granules production for the petrochemical-based packaging scenario. The next life cycle stage, intermediate processing, included paper packaging manufacturing processes such as milling, linerboard production, medium fluting, gluing, and box shaping, and plastic formation processes such as plastic film extrusion and other supporting activities. The third stage of the life cycle, transportation/use, includes the distribution of manufactured packaging to each destination point throughout the supply chain. The final life cycle stage, end-of-life (EOL), included waste treatment scenarios for recycling, incineration with energy recovery, and landfilling.

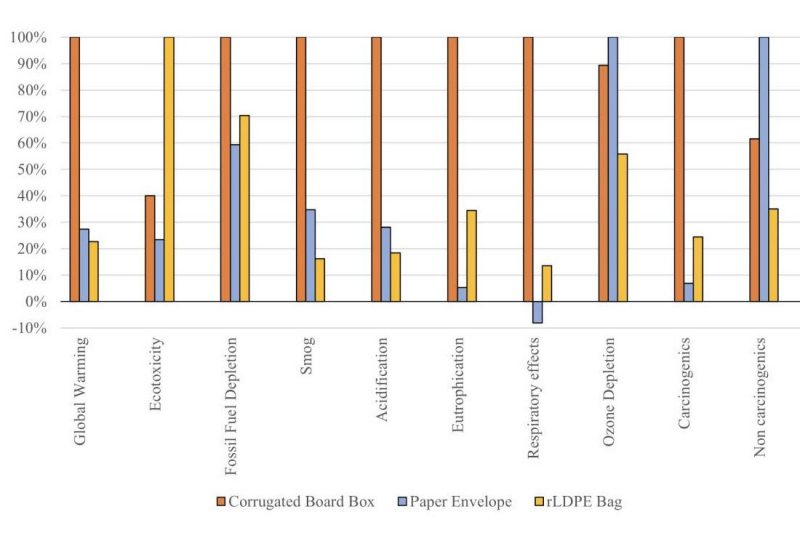

Image 3. Comparison of the relative environmental impacts generated by the corrugated board box, the virgin paper envelope, and the rLDPE bag. (For each impact category, the package scenario yielding the greatest impact was set to 100% to demonstrate relative impact reduction made possible via the alternative package options.)

The comparison of the three packaging scenarios reveals that the impacts of the e-commerce corrugated board box scenario resulted in the greatest environmental burdens across seven different environmental impact categories (Image 3). For global warming potential, the corrugated board box (0.299kg CO2-e) was 3.5 times the impact of the virgin paper envelope and 4.4 times the impact of the rLDPE bag. For fossil fuel depletion, the corrugated board box (0.156 MJ surplus) was 1.4 times the impact of the virgin paper envelope and 1.7 times the impact of the rLDPE bag. And for smog, the corrugated board box (0.0495kg O3-e) was 2.9 times the impact of the virgin paper envelope and 6.2 times the impact of the rLDPE bag. Similarly dramatic impacts were observed for the corrugated board box in impact categories for acidification (0.00216kg SO2-e), eutrophication (0.00159kg N-e), respiratory effects (0.000373kg PM2.5-e), and carcinogens (0.000000122CTUh). The primary driver behind these significant impacts of the corrugated board box is its relatively greater material weight. At approximately 209g, the corrugated board box required significantly more material input to produce and equated to a greater package weight to be transported.

Another factor driving the environmental impact differential between the corrugated board box and the rLDPE bag was the distance that the material was required to travel. For the paper-based packaging options, the input materials were located 3,252 km away from the packaging manufacturing facility, while the input materials for the rLDPE bag were able to be sourced from only 53 km away. Thus, the difference in transportation distance required by the industry collaborator’s supply chain system as well as the greater material weight of both paper-based packages contributed to significant environmental impacts from transportation activities. Although this specific material sourcing scenario cannot be generalized for other e-commerce companies, it greatly affected the sustainability of corrugated board boxes for the partner company.

Under the defined scope of this research, the corrugated board box resulted in the highest environmental burden of the three packaging options. Although paper is generally perceived to be the environmentally preferable material when compared to plastics, the rLDPE bag actually resulted in a lower environmental burden. While a high recycling rate helps to offset some of the environmental burdens of the corrugated board box and the virgin paper envelope, in most categories, it was not enough to overcome burdens associated with transportation, material requirements, and weight.

A sensitivity analysis found that supply chain distance optimization can help to improve the environmental performance of the paper-based options in these scenarios. But there is still a need for improvement. In particular, apparel brands operating in e-commerce markets should consider the geographic implications of, and transportation modes within, their package supply chain configurations. Future work is needed to explore the implications of varied package weights and percentage of recycled-content adjustments in order to balance package performance and its environmental impacts within the e-commerce system.