Research Highlight: The environmental benefits of increasing the stiffness of pallet top decks for unit loads carrying corrugated boxes

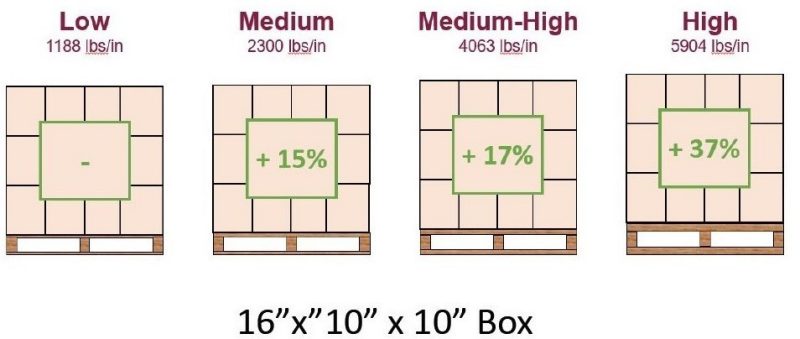

Image 1. Box compression strength changes due to pallet top deck stiffness.

This research project expanded on former graduate student Chandler Quesenberry’s research into the financial benefits of increasing the stiffness of pallet top deck boards for unit loads of corrugated boxes. In his initial project, Quesenberry determined that there was a 37% reduction in box compression strength when carried on lower stiffness pallets; hence, a savings of $1.30 per unit load when using a higher stiffness pallet. The objective of this subsequent study was to quantify the environmental benefits of increasing the stiffness of pallet top deckboards for unit loads of corrugated boxes.

The pallets and packages used for this research were built into two types of unit loads. Pallets were 48 in. x 40 in. stringer-class pallets with seven top and five bottom deckboards that were 3.5 in. wide and made of #2 kiln-dried SPF using two nails per connection. The 48 packages used to build the unit load were 16 in. x 9.75 in. x 20 in. Regular Slotted Container (RSC) style corrugated boxes. Unit Load 1 used 3/8 in. thick deckboards and B-flute corrugated board with 40 lb./in. nominal Edge Crush Test (ECT) value, while Unit Load 2 used 5/8 in. thick deckboards and B-flute corrugated board with 32 lb./in. nominal ECT value.

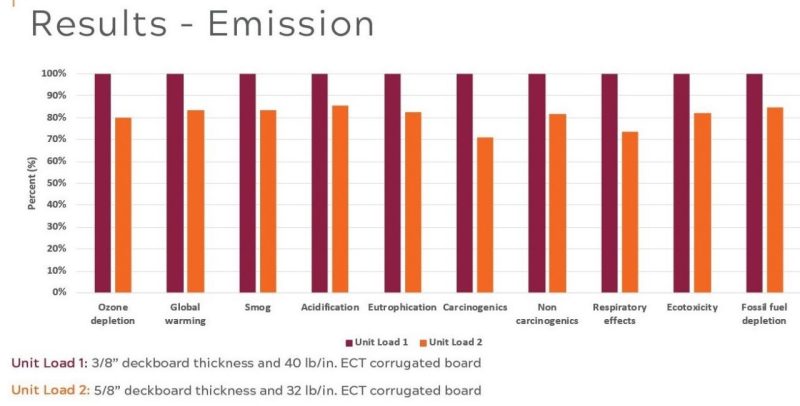

There are many aspects and items in a palletized unit load that can have environmental impacts. The manufacturing and recycling of corrugated board and liners impacts ozone depletion and global warming, consumes fossil fuels, and contributes to adverse respiratory effects. The electricity used during manufacturing and the waste treatment of corrugated boards contribute to acidification and ecotoxicity.

The life cycle analysis for this research project was conducted using SimaPro v9.0 LCA software based on ISO 14040.2006. It was done using the methods outlined in Traci 2.1 v1.05 and US-Canadian 2008 examining 1,000 unit loads and took into account raw material extraction, manufacturing, distribution, use, and end-of-life processes.

Image 2. Life cycle analysis (LCA) of emission impacts of palletized unit loads based on pallets’ top deckboard thicknesses.

The environmental impact was reduced by an average of 20%, and 17% less CO2 was released when the unit load with stiffer top deckboards was used. Considering these facts in addition to Quesenberry’s original research’s savings of $1.30 per unit load, it can be concluded that, for most distribution supply chains, it will be more beneficial overall for companies to use pallets with thicker top deckboards.