The Basics of Wooden Pallets

The pallet industry in the United States:

- 1.9 billion pallets are in use in the U.S. each year.

- Solid wood pallets make up 92% of the U.S. market.

- 441 million new wood pallets were manufactured in the U.S. in 2006.

- 321 million pallets were recovered/repaired/remanufactured in the U.S. in 2006.

Common Pallet Sizes in the U.S. (2011):

- 48" x 40" = 24.4%

- 42" x 42" = 4.8%

- 40" x 48" = 2.8%

- 48" x 36" = 1.5%

- 36" x 36" = 1.8%

- 48" x 48" = 3.8%

- 44" x 44" = 3.0%

- 800mm x 1200mm (Euro) = 0.7%

- Other (Custom) = 57.1%

Plastic Pallets:

Paperboard Pallets:

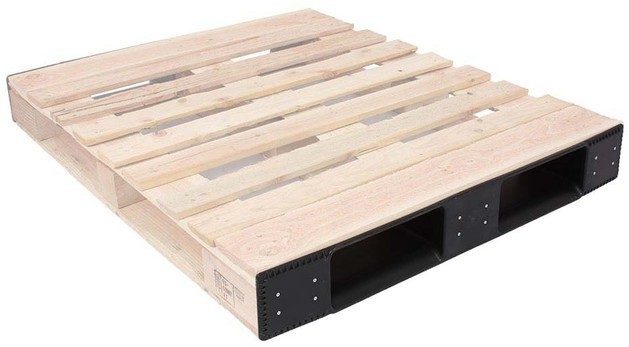

Wood Pallets:

Pallet design by entry method:

Two-way entry wood pallet:

Partial four-way entry wood pallet:

Four-way entry wood pallet:

Pallet design by base configuration:

Unidirectional base wood pallet:

Perimeter base wood pallet:

Cruciform base plastic pallet:

Solid Wood Pallets

79% of the U.S. market consists of solid wood pallets and 92% of pallet users use them

Advantages:

- Inexpensive

- Easy to prototype

- Strong

- Stiff

- Recyclable

- Can be designed using PDS

- Existing equipment and packaging is designed for the best performance using wood pallets.

Disadvantages:

- Fasteners

- Can harbor bugs

- Splintering

- Gaps between boards

- Give off moisture

- Variations between pallets

- Different lumber specs for different locations

Plastic Pallets

11% of the U.S. market consists of plastic pallets and 37% of pallet users use them.

Advantages:

- Bug free

- Durable

- Washable

- No fasteners

- Weather resistant

- Design potential

- Custom colors

Disadvantages:

- High purchase price

- Expensive to prototype

- Low friction

- Low stiffness

- Fire safety rating

- Not repairable

- Slower production times

Composite Pallets

18% of pallet users use composite pallets.

Advantages:

- Smooth deck

- Dry

- Bug free

- Good product protection

- Durable

- Design flexibility

- Can be designed using pallet design software

Disadvantages:

- High purchase price

- Expensive to repair

- Splintering

- Less recyclable

- Less water resistant

- Fasteners

Paper Pallets

11% of the U.S. market consists of paper pallets and 8% of pallet users use them.

Advantages:

- Lightweight

- Ergonomic

- Smooth deck surface

- Recyclable

- Lower freight cost

- Dry

- Bug free

Disadvantages:

- High purchase price

- Susceptible to moisture

- Poor performance with flexible loads

- Not durable

- Less product protection

Metal Pallets

0.8% of the U.S. market consists of metal pallets and 7% of pallet users use them.

Advantages:

- Strong and stiff

- Durable

- Recyclable

- Fire resistant

- Bug free

- Sanitary

- Dry

- No Fasteners

- Impervious to extreme temperatures

- Excellent product protection

Disadvantages:

- High purchase price

- Weight

- Sharp edges

- Low friction

- Susceptible to rusting

Fundemental pallet design parameters:

Strength

- Racking

- Static (floor stacks)

- Dynamic (fork tine movement)

Functionality

- Stiffness

- Durability

- Size

- Weight

COST!!!

Cost breakdown of packaging within a typical unit load...

$ 1.80 = Stretch wrap

$8-$9 = Pallet

$45 = Corrugated cases

$324 = HDPE 32oz bottles

$ 1.80 = Stretch wrap

$8-$9 = Pallet

$210 = 3.5 gallon plastic pails

Best practices for stiffer pallets:

- Always know the stiffness of your pallet design!

- Measure the increase in stress distribution before you make a decision.

- Consider the stiffness change of the pallet before modifying the support conditions.

- Stiffer is better!

When pallets aren't stiff enough, unit load failures can happen!

Best practices for more durable pallets:

- The life of the pallet is specified in number of trips.

- Expendable pallets need to last only 1 trip.

- Reusable pallets need to last more than 1 trip.

- Use butted double nominal 6" boards as lead-edge boards.

- Use hardwood boards for the lead-edge of a pallet.

- Use better fasteners.

- Protect the lead-edge blocks or stringers from impacts.

- Don't design pallets for more than 10 years.

- Don't design pallets for longer than you can retain ownership.

When pallets aren't durable enough, board failures can happen!

Technology used to improve pallet durability:

The below image shows a pallet protector attached to fork tines which helps to distributes the load on a larger area.

The below image shows a pallet protector attached to the front of the pallet reduces the severity of impacts on blocks, stringers, and lead-edge boards of the pallet.

Potential ways to improve durability:

- 5-6% increase in the number of fasteners used = 56% durability improvement in pallets.

- Butting lead-edge deckboards = 38% durability improvement in pallets.

- Split-inhibitors in lead-edge boards = 48% durability improvement in pallets.

- Use dense hardwood instead of medium density hardwoods = 38% durability improvement in pallets.

- Use dense hardwood instead of Douglas Fir = 165% durability improvement in pallets.

- Use air-dry pallets instead of green pallets = 43% durability improvement in pallets.

When pallets aren't durable enough, board splitting can happen!

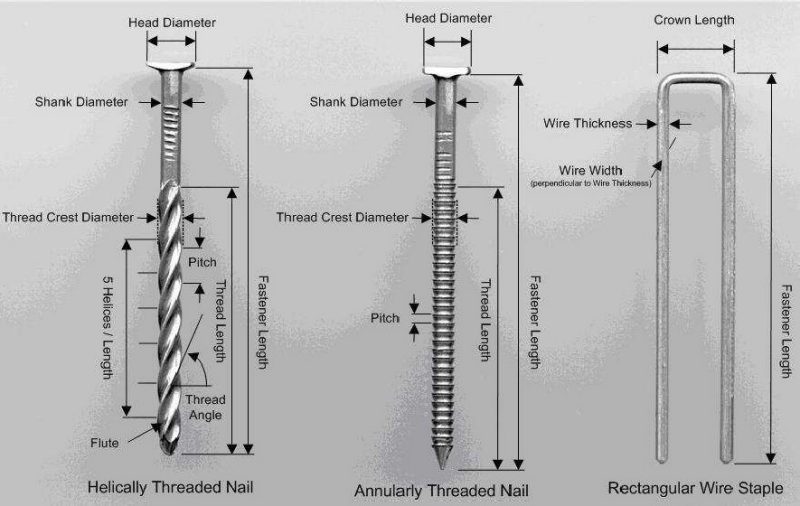

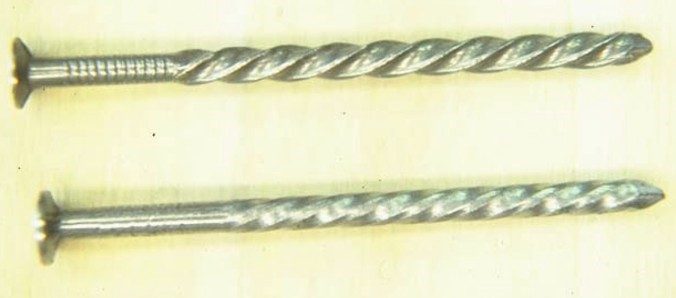

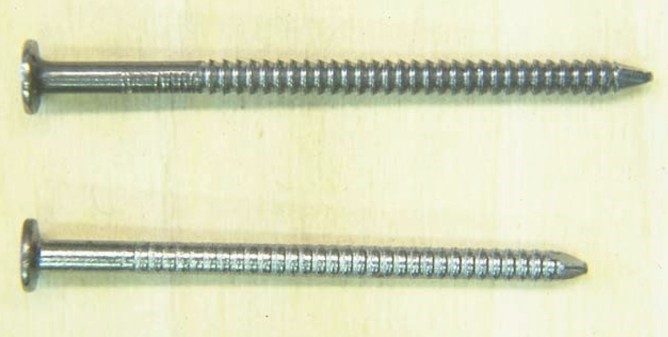

Basic pallet fasteners:

- Helically threaded nail

- Twisted square wire nail

- Annularly threaded nail

- Plain shank nail

- Round wire staple

Issues caused by fasteners: Fastener Splitting

Issues caused by fasteners: Fastener Bending

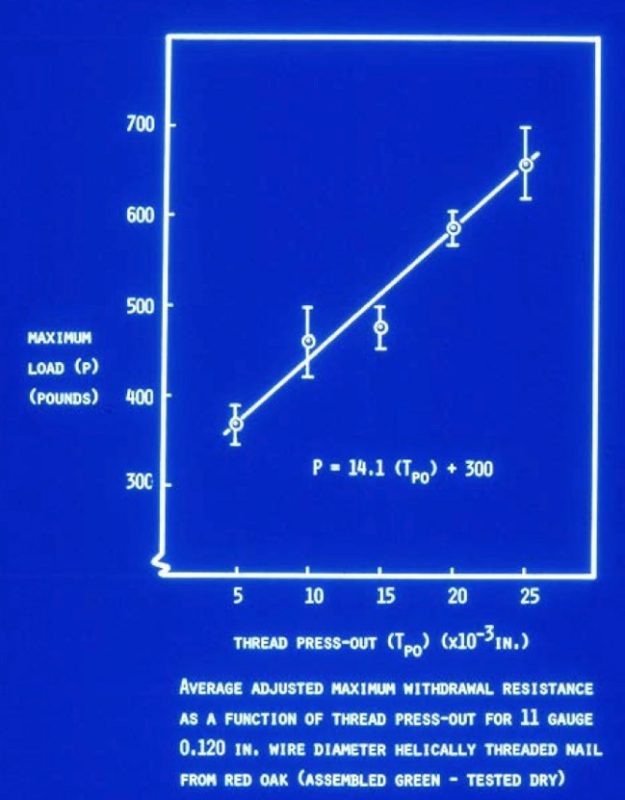

Effect of Thread Press-Out:

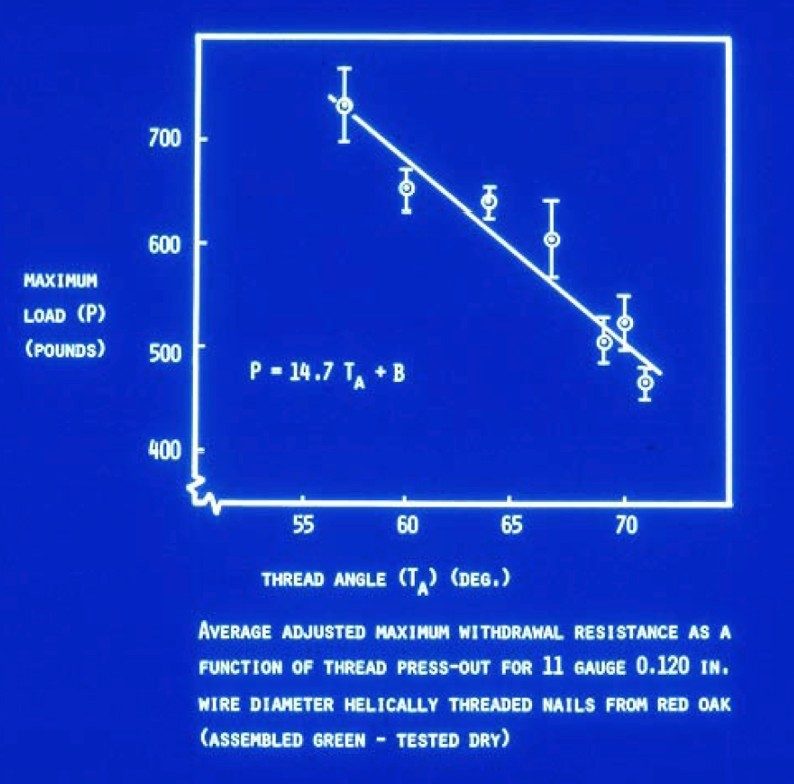

Effect of Helix Angle: