How to Prevent Moisture in Sea Containers

What causes moisture problems and how to solve them...

Large container ship fully-loaded.

Where does the water come from?

The water that is found inside shipping containers come from the air, packaging, pallets, and cometimes even the products that are stored in the container.

Air: Air always contains water in the form of water vapor. This is called humidity. When the temperature of the air is higher, more water can be contained in the air. Hence, higher temperature is what causes humidity levels to be higher.

Packaging: Any packages made from wood or woody material (corrugated, paperboard, OSB, etc…) can act like sponges and absorb moisture from their surroundings due to their hygroscopicity. The moisture content in the air and in the packaging materials strive for equilibrium. Therefore, if the moisture content of the air is high then it will be absorbed by the packaging until the moisture content of the packaging is high as well. Conversely, if air humidity is low, moisture will be released by the packaging until its moisture content is lowered as well.

Pallets: Due to woods’ inherent moisture content, wooden pallets can have a significant effect on the relative humidity of the air in a sea container. Wooden pallets are manufactured either from green or kiln dried lumber. For a pallet to give off water in a shipping container, it must be at or above an equilibrium moisture content (EMC) of about 30%. Pallets made with green wood can have a moisture content (MC) ranging from 50-100% and can easily contain more than ten pounds of water. Kiln dried pallets have a much lower moisture content (~19%), and they will not release moisture when shipped because this MC is below the EMC in sea containers. It is important to note that heat treating a pallet is not the same as kiln drying it. Kiln dried and heat treated pallets can have very different moisture contents. Therefore, one is not a suitable replacement for the others.

Products: Organic products are considered hygroscopic just like packaging and pallets; hence, they contain moisture which will be released or absorbed depending on the EMC in the sea container. Inorganic products on the other hand (plastics, metal, etc…) do not absorb moisture or release it. Inorganic products can be damaged during shipping but they do not contribute to moisture content.

Why does the water condense and cause problems?

Condensation forms inside the sea container because during shipping, temperature and humidity varies hugely and that variance can occur fairly quickly. If the air in the container heats up drastically, water evaporates from packaging/products by changing into vapor in the air. The water stays in the air until the temperature goes back down which then causes the water to condensate. Because, when the air in the container cools drastically, it can no longer contain a high level of moisture (it is said to have reached its dew point), and so the water falls out of its vapor form and into its liquid form. These temperature changes occur mostly from weather or climate differences. For example, a container shipped from Florida (hot and humid) to Greenland (cold and dry) experiences extreme climate change.

A study by Xerox showed that the most variances in temperature and humidity occur before and after the time on the ship. When the container is on the ship, it remains stationary and temperature and humidity changes occur very gradually. During the time before and after shipping, the container is loaded, unloaded, and stored for brief periods. These quick changes in location and the opening/closing of the container causes conditions to change drastically over hours instead of days.

Solutions:

Ventilation: Ventilating a shipping container can help to solve moisture problems by allowing air flow. When the water evaporates from packages and pallets and becomes vapor in the air, some of that vapor can be dispersed to the outside of the container which has a lower MC. However, this solution doesn’t work for every situation as the air flow works both ways. This can allow more moisture into the container if the outside MC is higher. The American Institute of Marine Underwriters created a proverb to remember whether ventilation will help or not: “Hot to cold, ventilate bold. Cold to hot, ventilate NOT.” Another problem is that often the ventilation won’t provide adequate airflow, and complete equilibrium won’t be reached.

Air vent on a shipping container.

Desiccants: Desiccants are items placed into the sea container that absorb excess water from the air; this effectively lowers the dew point inside of the container by pulling moisture from the air and from packaging/ pallets. Many common desiccants contain silica, activated charcoal, calcium sulfate, or calcium chloride as their absorption materials. The most common problem that desiccant users run into is not knowing how many desiccants to use. The standard for how many to use is DIN 55474. This industry standard gives a fairly complicated equation to calculate how many desiccants are needed based on the volume inside packaging, humidity, weight of hygroscopic packaging, moisture content factor, and several other variables.

Retailers can provide approximations for how many desiccants are needed based on the following equation or shipping companies can often calculate it for them. One company, Clariant, created a calculator online and in app form so that everyone can perform these calculations on their own.

n = 1/a · (V · b + m · c + A · e · D · t)

- n = number of the drying agent units (result)

- a = amount of water vapor to be adsorbed by drying agent unit V = volume inside the packaging in m³

- b = humidity content per m³ air

- m = weight of the hygroscopic packing in kg c = factor for moisture content

- A = surface of the barrier foil in m²

- e = correction factor with regard to the final moisture:

- D = water vapor permeability for the expected climate in g/m² t = transport and storage time in days

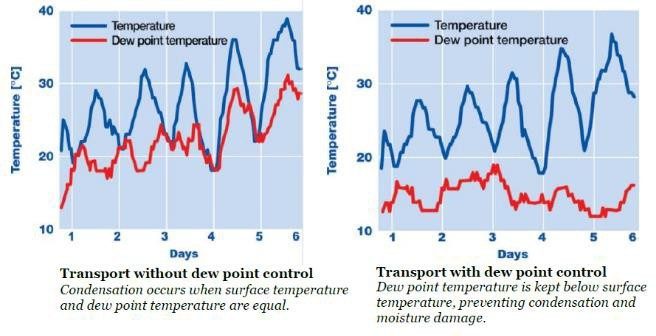

Graph showing temperature with and without dew point controls in place.

Shrink wrap/ vapor barrier packaging: This method is mainly used for electronics or other highly sensitive products. It involves sealing the item between layers of water vapor proof foil, placing a small desiccant into the package, and then vacuum sealing the item. This solution does nothing to prevent condensation throughout the shipping container but merely protects the products which could be effectively ruined by contact with that moisture. The packaging around the product, which contains the foil material, is often layers of polyethylene-foil-polyethylene for light products or scrim-foil-nylon for heavier items.

Shrink-wrapped packaging in wooden container.

Dry wooden pallets/ non-wood pallets: In almost all instances, products are placed into shipping containers on pallets. If green pallets are being used for sea containers, then incredible amounts of water are being shipped inside those pallets unnecessarily. By switching the pallets used from green pallets to kiln dried or non-wooden pallets, unneeded moisture is eliminated from inside of the container. Kiln dried pallets may even act to absorb some of the excess moisture in the air if they are significantly below the moisture content in the sea container. This means when the container’s air increases in temperature there won’t be as much excess water to evaporate, and when the air cools down again the dry pallet can help to absorb moisture to lower the dew point inside the container.

Summary:

Moisture is going to be present inside of shipping containers due to the inherent moisture content in:

- Air

- Pallets

- Packaging

- Products

There are various methods for preventing condensation from forming:

- Allow the air to escape the enclosed container through ventilation

- Use the proper amount of desiccant bags calculated by the DIN standard

- Shrink wrap or use vapor-barriers on the packages

- Use kiln-dried pallets instead of green pallets

References:

1. http://infostore.saiglobal.com/store/details.aspx?ProductID=1794878, accessed May 12, 2016

2. http://www.litco.com/news/desiccant/how-to-prevent-excessive-cargo-container- condensation-and-product-damage-with-desiccants.htm, accessed May 12, 2016

3. http://www.tropack.com/products/trockenmittelbeutel-berechnungstab-bps.htm, accessed May 12, 2016

4. https://www.aimu.org/aimupapers/1ContainerSweatandCondensation.pdf, accessed May 12, 2016

5. http://www.clariant.com/en/Business-Units/Functional-Minerals/Cargo-and-Device- Protection/DESI-PAK-Calculator, accessed May 12, 2016