Properties of Shredded Wooden Pallets

The objective of this research was to characterize the physical and chemical properties of wood particles produced from mechanically ground discarded wood pallets to determine their suitability for poultry litter, livestock bedding, and fuel.

Overview

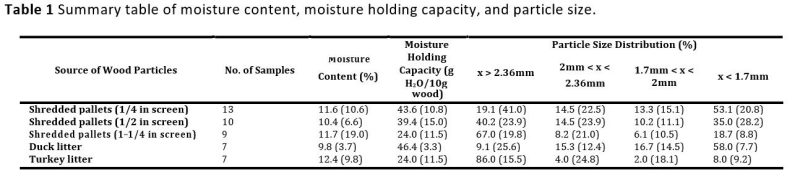

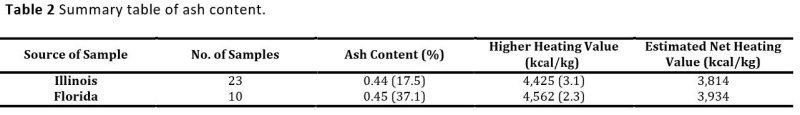

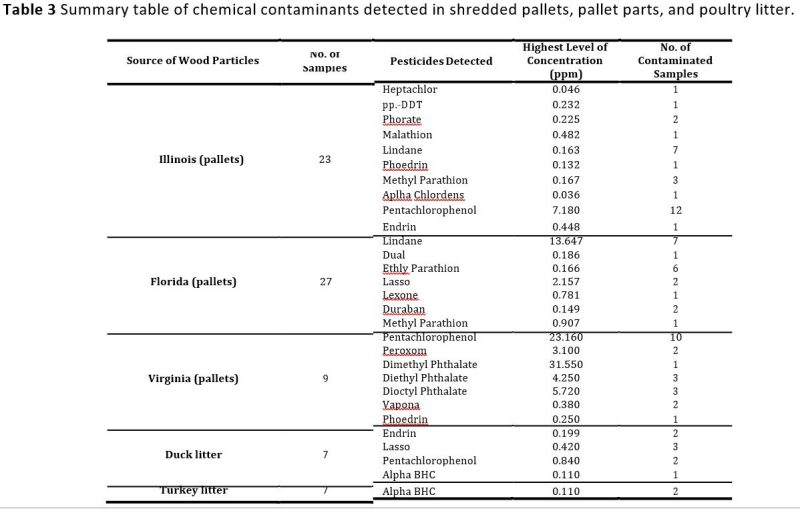

An estimated 2.9 billion board feet of wood waste was generated from discarded pallets in 1987, most of which was disposed of in landfills. However, available landfill space is decreasing, landfill costs are increasing, and solid waste reduction has the nation's attention. Problems and costs associated with the disposal of discarded pallets are beginning to alarm the pallet producing and pallet consuming industries. Fortunately, there are potential uses for discarded pallets. The objective of this research was to characterize the physical and chemical properties of wood particles produced from mechanically ground discarded wood pallets. These characteristics include moisture content (MC), ash content, higher heating value, moisture holding capacity, particle size distribution, and level of chemical contamination. This information was used to determine the suitability of the material for marketing as poultry litter, livestock bedding, and fuels. The wood particles were found to be low in MC and ash content and had a relatively high net heating value, rendering the material an excellent industrial fuel. The wood particles were also found to have good moisture holding capacity, an acceptable level of fines, and low levels of chemical contamination, rendering the material an excellent poultry litter or animal bedding.

Materials and Methods:

Samples of wood particles from a pallet grinding operation in Illinois were taken on every other operating day between May 5 and June 25, 1986. A total of 23 samples were collected. Samples of wood particles from a pallet grinding operation in Florida were also taken on a periodic basis from May 5 to July 7, 1986. A total of 27 samples were collected. An additional nine samples were taken, twice daily between April 20 to 24, 1987, at a pallet recyc1ing operation in Virginia.

For comparative purposes, samples of poultry litters were also taken from the Illinois and Virginia regions. This litter consisted of pine shavings and sawdust, as well as hardwood planer shavings. All samples were field collected, sealed in plastic bags at the collection point, and shipped to the William H. Sardo Jr. Pallet and Container Research Laboratory at Virginia Polytechnic Institute and State Univ., Blacksburg, Va. (VPl&SU).

The following tests were performed on the samples:

- Moisture Content (MC): ovendry method.

- Ash content: according to ASTM D 1102-‐‑56, "Standard Methods for Ash in Wood."

- Higher Heating Value (HHV): according to ASTM D 2015-‐‑66, "Standard Methods for the Gross Calorific Value of Solid Fuel by the Adiabatic Bomb Calorimeter."

- Moisture holding capacity: find more information in the full paper.

- Particle size distribution: find more information in the full paper.

- Concentration of organophosphate, organochlorine, and pentachlorophenol contaminants: determined by the Pesticide Research Laboratory, Department of Biochemistry and Nutrition, VPI&SU, using gas chromatographic techniques. A Tracor 540 and a Micro-‐‑Tek 220 GC equipped with ECNi 63, FPD, and FID detectors were used. The column packing was as follows: 1.5/1.95 percent, OC-‐‑17/QF-‐‑1,170 to 225°C and 10 percent, SP-‐‑2100, 170° to 225°C column temperatures. The procedures used are described in Fullerton et al. (4) and the Environmental Protection Agency's manual (3).

Results:

More information can be found in the full research paper:

White, M.S., and McLeod, J. (1989). Properties of Shredded Wood Pallets. Forest Products Journal, 39(6):50-54