Phytosanitary Regulations for Packaging (ISPM 15)

What are the appropriate sanitation procedures for wood dunnage and wood packaging to deter the spread of destructive pests and mold...

What is ISPM-15?

The International Standards for Phytosanitary Measures publication 15 (ISPM 15) is a globally recognized regulation that specifies appropriate sanitation procedures for coniferous softwood and non-coniferous hardwood that is used as raw wood packaging materials.2 Investigations have found that if untreated wood is used for wood packaging, it quickly promotes the spread of environmentally destructive pests by directly delivering them to a different region of the world that they would not reach naturally.3 However, this regulation does not all apply to all wood packaging products.

Regulated Materials:

- Packing cases

- Boxes

- Crates

- Pallets

- Dunnage

- Spools

- Reels

- Cable drums

Exempted Materials:

- Processed wood materials (oriented strand board, particle board, veneer, plywood).

- Specialized gift boxes for cigars and wine.

- Heated wine and spirit barrels.

- Wood with thickness less than 6mm.

- Attachments to shipping containers or vehicles.

- Wood shavings, wood wool, and sawdust.

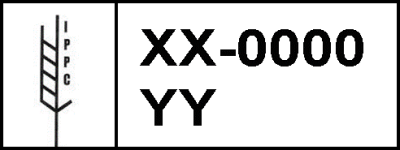

The following is the mark that the International Plant Protection Convention (IPPC) requires to be present on all phytosanitized wood pallets.2

XX – the two letter ISO country code

0000 – the ID marker of the wood treatment agent or packaging manufacturer

YY – indicates the type of treatment used (see Approved Treatments)

History of ISPM-15:

In 2003, ISPM 15 was introduced and then it was implemented in both Canada and the United States in January and September of 2006, respectively.1 Today, ISPM 15 is governed by the IPPC which works hand-in-hand with countries that are members of the United Nations (UN).1 Currently, there are over 70 countries that have adopted the regulations and standards set forth by ISPM 15.1

Approved Treatments:

Sanitization of pallets via heat treatment is perhaps the most common industrial practice for the extermination of pests from wood pallets and wood packaging. ISPM 15 requires the temperature of the wood packaging material be taken from the core of the packaging since that is where invasive pests reside. Some of the common treatments are described below2:

- Heat Treatment (treatment code HT): When utilizing this method, wood packaging materials are subjected to a heat chamber (either with conventional steam or dry kiln heat), where they are required to remain for a minimum of 30 minutes once the core temperature of the thickest component reaches 56C.

- Heat treatment using Dielectric Heating (treatment code is DH): This type of treatment utilizes a process similar to what happens in a microwave. Wood packaging material is exposed, throughout the entire profile of the wood, to microwaves, at 60C, for at least one continuous minute. In order for this method to comply with ISPM15, the 60C temperature minimum must be reached within 30 minutes of the beginning of the application.

- Methyl bromide fumigation (treatment code is MB): Perhaps the most hazardous and expensive method, MB fumigation requires that wood packaging materials be exposed to MB gas for over 24 hours at a given temperature. The use of this method must be approved by the National Plant Protection Organizations (NPPO). This treatment is currently being phased out of the industry because the gas could potentially contaminate food products.

Regulated Species:

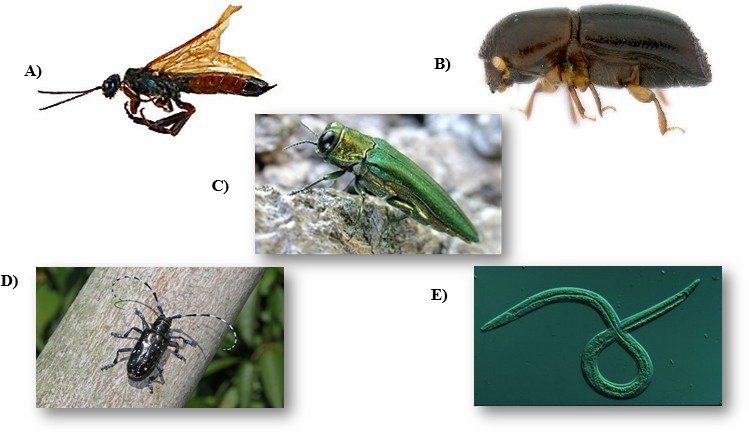

There are hundreds of insect species that wreak havoc on woody plants, especially trees. Primarily, it is the insects that infest the trunks of trees that are the greatest cause for concern because the trunks are what are harvested to produce wood packaging materials1. Some of the most notorious species that ISPM 15 regulates are:1

A. Sirex Woodwasp (Sirex noctilia): The Sirex Woodwasp mainly attacks pine trees. Originating from Africa, Asia, and Europe, this large insect is detrimental to the pine trees of North America. This invasive species is very prevalent in the United States, but parasitic nematodes have helped reduce the species’ numbers.

B. Ambrosia Beetle (Megaplatypus mutates): Unlike most other tree-consuming bugs, Ambrosia Beetles travel through the bark of the tree to access sapwood. This insect survives on the fungi generated while boring into the tree, as shown in Figure 5. Once the beetles attack the tree, it is very difficult for the tree to survive.

C. Emerald Ask Borers (Agrilus planipennis): Originating in Asia, Emerald Ash Borers specifically attack ash trees located North America. The adults harmlessly consume the tree’s leaves, but the larvae destroy the interior bark, which eventually kills the tree. After the discovery of these beetles in 2002, the species has continuously spread to surrounding areas. As shown in Figure 4, the insect is now present in most of the eastern United States and parts of Canada.

D. Asian Longhorn Beetles (Anoplophora glabripennis): These beetles attack hardwood trees in the north-eastern United States and in southern Canada. Asian Longhorn Beetles are most prevalent at the end of spring but continue to be active until fall. These large beetles are from China, and they can be very destructive to both hardwood trees and their surrounding habitats.

E. Pinewood Nematodes (Bursaphelenchus xylophilus): Originating in Japan, the Pinewood Nematode causes significant damage and death to pine trees. Figure 6 shows an adult version of the insect. Currently, the species is present in the eastern and central parts of the United States. Nematodes typically attack older trees, and wilted needles are the first sign of the tree’s infestation.

Why is this important for pallet companies?

In Canada alone, over $25 billion of forest products were exported in 2012. With such a large volume of wood crossing borders, it is vital that those resources be protected against the species listed earlier. From 2003-2013, the city of Vaughn, Ontario spent an estimated $35 million in an attempt to eradicate the Asian Long-horned Beetle from its lumber supply.

As a pallet company, it is imperative to ensure that the pallets under your authority remain sanitized and free of quarantined pests because the consequences of failing to do so can be catastrophic. In an industry that tries to reduce the amount of material cost without compromising the package performance, a potentially massive loss of resources to the aforementioned species would set the pallet industry reeling. Therefore, it is essential that all export pallets be treated using an ISPM 15 compliant treatment.

References:

1. Haack, Robert A. "ISPM No. 15 and the Incidence of Wood Pests: Recent Findings, Policy Changes, and Current Knowledge Gaps." The International Research Group on Wood Protection (n.d.): 3. IRG Secretariat. Web. 14 Apr. 2016.

2. "ISPM15 - Site Map." ISPM15 - Site Map. Produced by the Secretariat of the International Plant Protection Convention, 2009. Web. 12 Apr. 2016.

3. "International Standards for Phytosanitary Measures." Regulation Of Wood Packaging Material In International Trade (n.d.): n. pag. Secretariat of the International Plant Protection Convention, 2009. Web. 12 Apr. 2016.

4. Wolff, Gregory. "Implementation of ISPM 15 for Wood Packaging Moving between Canada and the United States." Canadian Food Inspection Agency (n.d.): n. pag. Border Commercial Consultative Committee, 12 Feb. 2014. Web. 13 Apr. 2016.