Research Highlight: Investigating the Interactions Between Pails and Pallets and Pail Compression Strength

Image 1. Representative set up of pail crushing.

This is the second part of a two-semester undergraduate research project conducted to learn more about the interaction between pails and wooden pallets. The research was funded by the Pallet Foundation of the National Wooden Pallet and Container Association (NWPCA). Meredith Brooks, a junior pursuing a degree in packaging systems and design (Image 2), and Michael Phelps, a senior pursuing a degree in sustainable biomaterials (Image 3), were selected for this project. Both students were taking part in the Distribution Packaging Internship Program through CPULD and had been working as laboratory technicians in the pallet testing lab prior to being selected.

Pails are frequently used in industry to ship smaller quantities of liquid products such as paint. Due to their design, pails are sensitive to the support conditions such as the size of deckboard gaps and the position of the pail on the deckboards. The project had two main goals: the first was to gain further understanding on the mode of pail failure under different stacking conditions, the second was to investigate how deckboard gaps and overhang affects the failure mode and mechanical strength of pails. Prior to this project, effects of these factors have only been investigated using corrugated boxes.

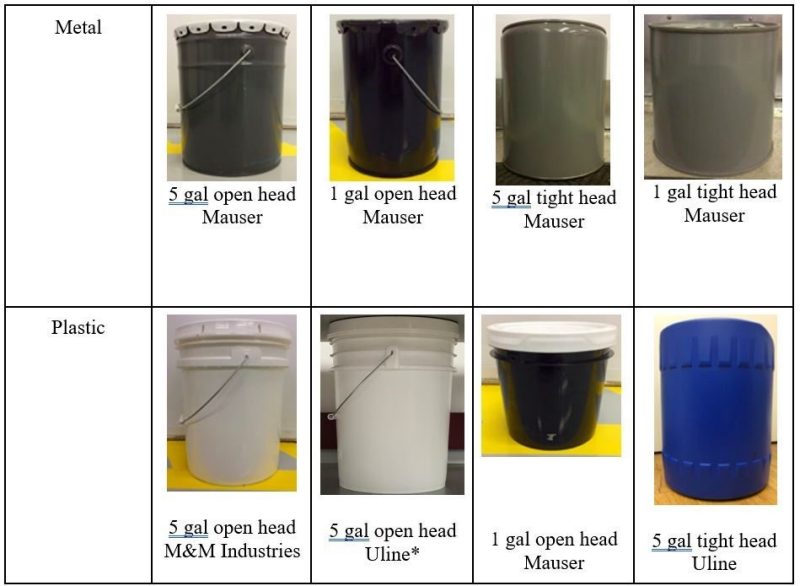

For the first phase of the project, eight pail designs were investigated (Image 4). They varied in volume, material, dimensions, and the type of closure. Each of the pail designs was placed in a compression tester with a data collection program to measure the amount of load needed to fail the pail design. The plastic pail designs were centered and tested in the Lansmont Squeezer, which had a fixed platen with a 5,000 lb. load cell. The metal pail designs were tested in the MTS 10/GL as it had a higher load capacity. The maximum load before failure was recorded using a computerized data collection system for each test. Each of the pail designs were tested using three different stacking conditions: single stack, double stack, and no lid configurations.

Representative photos of pails

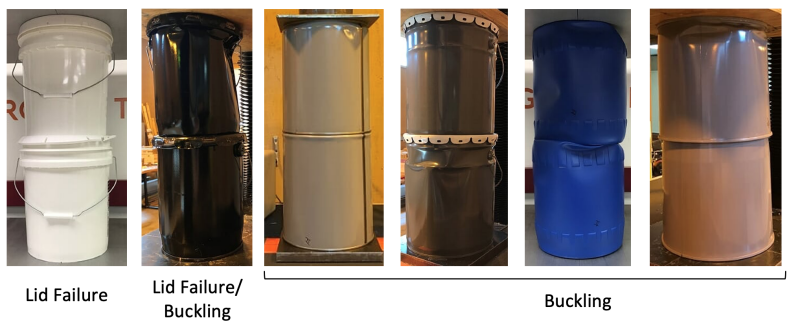

The modes of failure for the compression strength tests varied between the different stacking configurations and pail designs. The two modes of failure that were observed were sidewall buckling and lid failure (Image 5). The most common mode of failure for all of the designs and configurations was sidewall buckling; however, in some of the double stack tests, the mode for failure was lid failure.

It was observed for all of the pail designs, except for the 5-gallon tight head metal, that the average peak load at failure decreased when the pails were double stacked, which led to the conclusion that the compression strength of the pails decreases when double stacked. The decrease in average peak load observed during the double stack tests may have been caused by a redistribution of the concentration of the load from the top pail to the interior portion of the lid of the bottom pail rather than a rigid plate evenly distributing the load around the rim of the lid. This redistribution of load concentration may have also been the cause of the lid failure seen in some of the double-stack tests.

The most common pail used in industry is the 5-gallon open plastic pail. When tested, these pails fell in the middle of the range of compression strength. The average peak load capacity for the single stack configuration was about 3,000-4,000 pounds. For the double-stack configuration, the average peak load capacity ranged between 2,500-2,800 pounds.

It was observed that the closed head metal pails, both 5-gallon and 1-gallon, are the stronger pail designs. The weakest designs were the 1-gallon open plastic pails and the 5-gallon closed plastic pails. The rest of the designs were relatively similar in compression strength. While the size of the pail did not have a significant effect on its compression strength, the material had a major influence.

Image 5. Representative modes of failure for the single stack pail compression test.

During the second phase of the study, the effect of deckboard gaps and overhang was investigated. The pails were double stacked for this experiment and the loading was conducted in the Lansmont Squeezer compression tester. The modes of failure for each deckboard configuration were the result of a failure in the bottom pail (Image 6). Pail buckling was the primary mode of failure for each setup, with the exception of the 2 in. gap configuration, which also had a lid failure. The results showed that increasing the size of deckboard gaps can reduce the compression strength by 21.8% while the increase in overhang decreased the compression strength by as much as 48.7%. This trend aligns with similar research done on corrugated boxes. However, the severity of the decrease in compression strength was slightly greater than that of corrugated boxes. The students are planning to continue the study during fall 2020 with more replicate tests to be able to produce results that can be produced statistically.

Image 6. Representative modes of failure for the 2 in. gap and 4 in. deckboard gap configurations