Dr. Laszlo Horvath Presented Research About the Effects of Pallet Top Deck Stiffnesses on the Strength of Corrugated Boxes to the IAPRI Conference

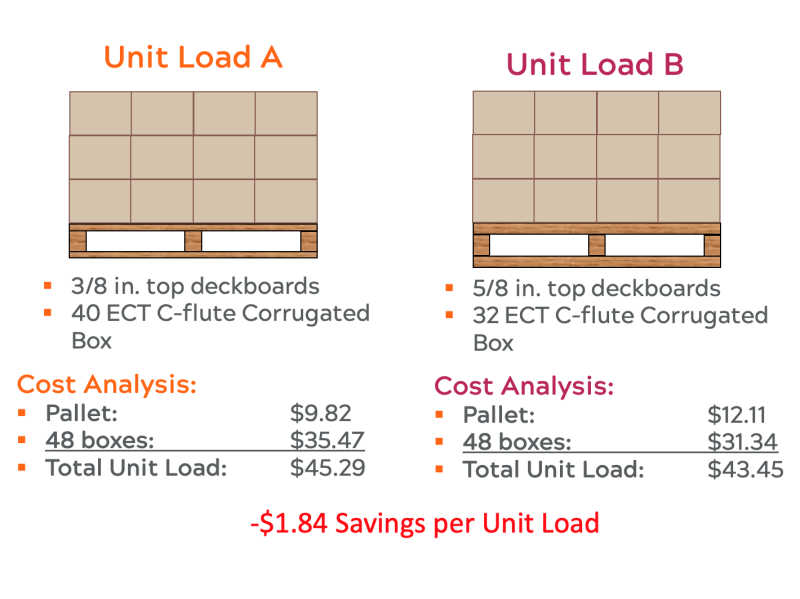

financial analysis of unit loads

Dr. Laszlo Horvath, director of the Center for Packaging and Unit Load Design (CPULD) at Virginia Tech, was recently asked to present the findings of his graduate student Chandler Quesenberry’s research project, which focused on quantifying how pallet top deck stiffness levels affect the compression strength of asymmetrically supported corrugated boxes (Image 1). The presentation was given to the IAPRI conference, which was held virtually in 2020.

A unit load is formed with a pallet as the base, supporting a group of packaged items, usually in corrugated boxes and stretch-wrapped to keep them together and in place on the pallet. When these unit loads are moved through the supply chain, the bottom boxes in the unit load experience significant compression stresses. The harshest condition for these boxes is when unit loads are stored in floor storage sometimes double, triple, or even stacked five levels high to conserve space in a warehouse. When boxes can no longer support the load, their sidewalls buckle (Image 2), which often leads to unit load instability or even product damage.

Image 2. Showing sidewall buckling of corrugated boxes on less stiff pallet deck.

Corrugated boxes are designed to survive the known hazards of physical distribution. During design, their strength is often determined using physical tests or using the McKee equation (an industry accepted formula). Then the strength of the box is adjusted using factors designed to consider the effect of environmental conditions such as relative humidity, storage time, and various pallet-related factors (e.g., the effect of deckboard gaps, interlocking, overhang, and unsupported box corners).

However, the effect of pallet top deck stiffness is not currently considered. This means that, during box design, we assume that the boxes will act the same whether they are placed on a single use pallet with thin, low-stiffness deckboards or a pool pallet with a really stiff top deckboard. Quesenberry’s research project looked into this by studying four different levels of top deckboard stiffness on a 48 in. x 40 in., 2-way, non-reversible, flush GMA-style wood pallet (Image 3).

Image 3. 48 in. x 40 in., 2-way, non-reversible, flush GMA-style wood pallet

The results of the study showed that when the pallet top deck stiffness increased from low to high, the strength of the corrugated boxes increased by as much a 37%. The results were consistent for all investigated scenarios (Image 4). The increase in compression strength as a function of pallet stiffness was gradual; however, the change between the boxes on medium and medium-high pallets was not statistically significant using 95% confidence interval. The change between the other scenarios was significant, as indicated by the different letters on the top of the bar charts.

Image 4. Box compression strength as a function of box design and pallet stiffness

This study also investigated the bending of the deckboards throughout the tests. The researchers wanted to see whether there were any observable differences in pallet top deck deflection at the investigated test load levels. It was found that the deflection of the lower stiffness deckboards was almost twice as much as the deflection of the high stiffness deckboard. This indicates that the support under the boxes was different, and, for the lower stiffness deckboards, it was more uneven. The pressure distribution was also investigated and found that for the lower stiffness deckboards, the pressure redistributes and creates a significant pressure concentration on one side of the box. This same behavior was observed for all investigated box sizes and materials. This phenomenon could explain the reduction of the box compression strength.

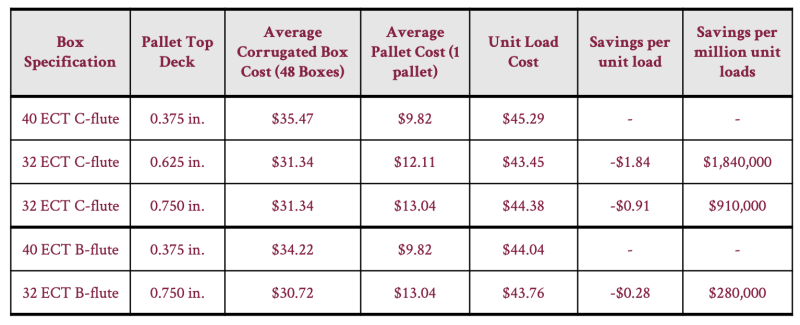

So, a certain box compression strength can be attained by re-designing the unit load in multiple ways. Conventionally, this is done by adjusting the boxes’ board grade and flute type. But, using this systems-based design methodology, the boxes’ compression strength can be changed by utilizing the pallet top deck stiffness effect on box performance — it is possible to deliver similar changes to the boxes’ compression strength without changing the boxes’ cost. Utilizing the effects of pallet top deck stiffness on box compression performance found by this research project, a unit load cost analysis was finally conducted showing that a stiffer pallet can be used to carry boxes with less board material; hence, it can reduce the total unit load packaging cost (Image 5).

Image 5. Financial analysis showing unit load savings based on thicker top deckboard instead of higher-grade corrugated board.

Three box suppliers and three pallet suppliers were surveyed to determine the total costs of hypothetical unit loads. The reasoning behind a cost analysis was to investigate potential per unit load cost savings from altering pallet top deck stiffness instead of adjusting boxes’ board grade or flute type to obtain a better compression strength performance. According to this study, the overall cost of the unit loads with stiffer deckboards is less than the cost of unit loads using higher grade corrugated board to obtain the desired compression strength. Changing the pallet cost instead of the box cost will result in a $1.84 savings per unit load, which could add up to $1,840,000 in savings per year for companies with at least a million palletized unit loads in their supply chain (Image 5).

Additionally, the average pallet price reported was the initial purchase price of the pallet, but that initial price doesn’t account for the lifespan of the pallet. If a company has control over its supply chain and reuses pallets for additional future unit loads, the initial price accounted for decreases by the number of life cycles of the pallet. A stiffer pallet, utilizing thicker deckboards, is more durable during handling compared to the same design with thinner deckboards, which results in more life cycles. Companies that recycle rather than reuse their pallets still experience cost savings by using stiffer pallets because they will have less deckboard damages that would result in a higher recycling price. Using more durable pallets also creates the added benefit of reducing the chance that the pallet gets broken during shipping and handling, which reduces downtime and the chance for product damage.

Overall, the study revealed that box designers should be aware of the variability of pallet top deck stiffnesses and how it can impact the compression performance of boxes shipped on pallets. Designers should use pallet top deck stiffnesses to their advantage as an option for cost cutting or redesigning unit loads to achieve better performance. The pallet top deck stiffness should be included as an adjustment factor for current pallet and box design methodologies, similar to other box-pallet factors such as pallet gaps, overhang, pallet pattern, and stacking alignment. This research showed that pallet top deck stiffnesses can be used to save a company money during its distribution processes if this knowledge is taken into account during the design process.

This was a summary of Chandler Quesenberry's graduate research project which was overseen by Dr. Laszlo Horvath, Dr. John Bouldin, and Dr. Marshall White. These results have also recently been published in the international journal Packaging Technology and Science on September 2, 2020. The link to this peer reviewed article is here: The effect of pallet top deck stiffness on the compression strength of asymmetrically supported corrugated boxes.