Graduate student, Mary Paz Alvarez, invited to give IAPRI presentation about research on palletized drums in warehousing and distribution

Mary's research on palletized drums

Mary Paz Alvarez (Image 1), under the guidance of Dr. Laszlo Horvath, Virginia Tech, and Farhad Shahabi, NWPCA, is working on a research project looking at how well wooden pallets perform during distribution when they’re carrying large drums. The research project is funded by the Pallet Foundation of the National Wooden Pallet and Container Association (NWPCA). Mary was recently asked to present the current finding of her research at the IAPRI conference, which was held online this year due to the COVID-19 pandemic.

Pallets are an integral part of the modern-day supply chain. Pallets are currently designed assuming that they will be supporting a uniformly distributed and flexible load; however, the types of product being carried by the pallet can cause the load to redistribute unevenly on the pallet. This phenomenon is called load bridging. Load bridging has been extensively studied for unit loads of corrugated boxes. It was observed that during pallet deflection (bending), the pressure of corrugated boxes is redistributed to the ends of the pallet instead of being distributed evenly across the pallet’s top deck. This pressure redistribution can have a large impact on how much load the pallet can ultimately carry, which can affect the sustainability and safety of the unit load.

Even though it is one of the main phenomena that affect the load capacity of pallets, load bridging had not previously been characterized for drums. Understanding the effect that drums have on deflection/load bridging will allow pallet designers to design more efficient and sustainable pallets. So the objective of Alvarez’s study was to gain more understanding about how pallet deflection, and the pressure distribution on top of the pallet, is influenced by the shape, weight, and material of drums.

The experiment included four 48 in. x 48 in. stringer class, non-reversible pallet designs with 1/2 in. and 5/8 in. top deckboards (Image 2). All lumber used to construct these pallets was kiln dried to 19% moisture content and had a grade of standard or better. The investigation utilized four steel drums and four plastic drums filled with water (Image 3).

Pallet types for Alvarez research

Drum types for Alvarez research

When creating the drum unit load, a pressure mat (Tekscan model #7202) was sandwiched between two .06 in. thick polypropylene sheets, and a .063 in. EPDM roofing rubber mat was placed on the pallet first. The Tekscan equipment utilized I-scan software, which is what was used to record the pressure mat readings for each support condition that the unit load experienced. The drums were loaded on individually as close together as they could possibly be without any overhang. There was no containment used on the drums.

The research’s experimental design was based on two different drum materials, four different stringer pallet stiffnesses, and five different support conditions. Three repetitions were conducted for each combination of drum material and pallet design. The experiment was conducted in cycles following the same order of steps: single stacked support, double stacked support, warehouse racked support across the width, and warehouse racked support across the length. Deflection measurements and pressure mat readings were collected for every support condition. Each pallet experienced three cycles with both drum materials.

The effect of drum material on pallet deflection is statistically significant for every investigated support condition:

· In warehouse racking across the length support condition, the difference averaged 23%.

· In warehouse racking across the width, it averaged 29%.

· In single and double stack floor support, it averaged 93% and 59%, respectively.

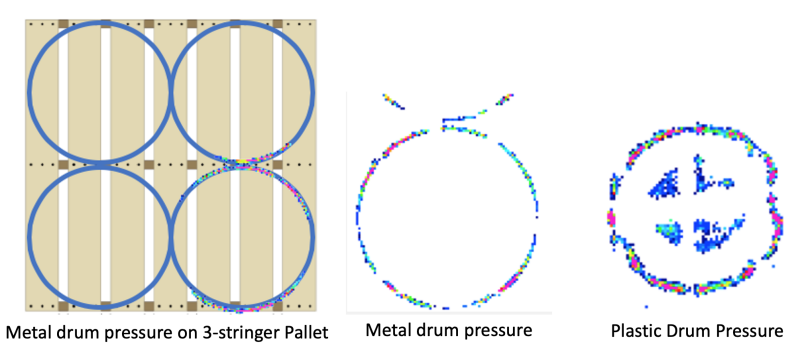

The difference between the behavior of the metal and plastic drums was attributed to their material rigidity. The plastic drums are more flexible than metal drums; therefore, they exhibit lower load bridging because they are able to follow the bending of the pallet more. This was confirmed by measuring the pressure distribution where more even pressure distribution was found for plastic drums, while the pressure for metal drums was mainly found under the chimes (Image 4).

metal drum pressure mat for Alvarez research

In short, Alvarez found that the drum’s material had a significant effect on the deflection of the pallet. Metal drums resulted in 46%-81% reduction in pallet deflection when compared to an airbag. Meanwhile, plastic drums created concentrated pressure areas on the pallet that, in most cases, resulted in more pallet deflection than what was measured for the airbag. These results indicate cost saving opportunities, especially for pallets supporting metal drums in scenarios where the load capacity of the pallet is limited by pallet deflection. However, it was also revealed that there is a significant difference in pallet behavior depending on the type of drum; therefore, the exact drum material and design need to be considered during pallet design.