Package Drop Testing

Throughout the manufacturing and delivery process, it’s likely that a packaged product will experience shocks of all types – the most common being when a package is accidentally dropped either while being manually handled or being mechanically moved.

Free Fall Drop Testing aids us in the design of sturdy packaging that will not only protect the product from incurring damages if/when it is dropped during handling or transport, but the packaging will stand up to being dropped repeatedly, and it will continue to protect the product within after multiple drops.

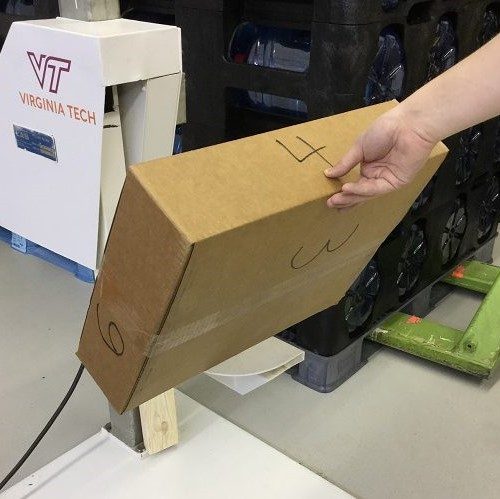

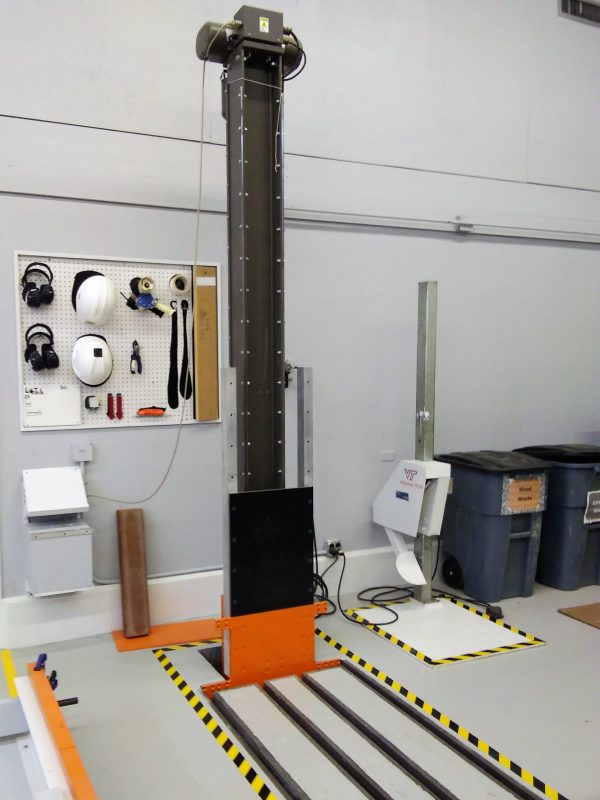

Equipment used for Free Fall Drop Testing:

Lansmont: PDT Drop Tester 300

Max Drop Height: 90 inches

Min Drop Height: 1 inch

Max Package Weight: 500 lbs.

Base Plate Size: 60 in. x 30 in.

Lansmont: PDT Drop Tester 80

Max Drop Height: 72 inches

Min Drop Height: 12 inches

Max Package Weight: 177 lbs.

Base Plate Size: 36 in. x 36 in.