Research Highlight: Shocks experienced during South Korean parcel delivery

korea sensor

Our director, Dr. Laszlo Horvath, received funding from a private international company to investigate the parcel delivery system in South Korea in order to be able to recommend testing protocols for their system. Graduate student, Saewhan Kim, PhD (Image 1a), was assigned to this research project. He collected information about the level of shocks and vibration experienced by packages transported throughout the South Korean parcel delivery system (Image 1b), particularly during the last-mile delivery portion of distribution. The collected data allowed the research team to use drop tests and vibration profiles that simulated the hazards actually experienced during South Korean parcel delivery. This data was then compared to internationally used packaging testing standards in order to help develop a proposed testing plan for Korean e-commerce package testing.

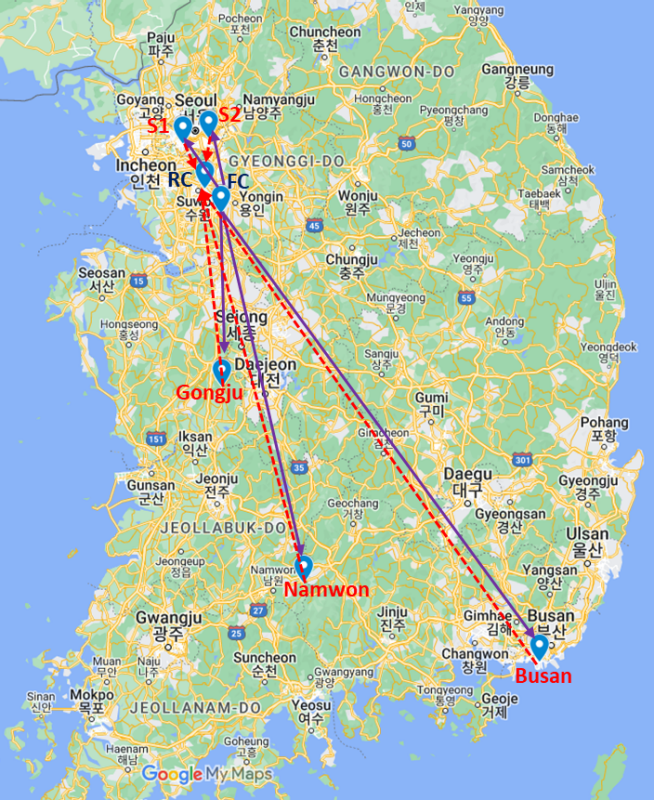

Before flying to South Korea, Kim built decoy packages to be used to test the parcel delivery systems (Image 2). These decoy packages took dozens of one-way trips between distribution facilities (Image 3) in order to collect the most data possible about the shocks that packages experience. The shock data was then analyzed and the equivalent drop heights calculated based on the measured delta velocities. Additionally, to collect the last-mile vibration environment, multiple parcel delivery vehicles were instrumented with Lansmont Saver 3x90 data loggers and GPS units. The vibration profiles of each transportation mode were recorded and used in the laboratory simulations.

The drop study aimed to create a laboratory test procedure that simulated the real-world parcel shipping environment of a one-way shipment. In this study, all data was analyzed as individual one-way shipments in order to ensure accurate results that could guide the creation of an effective laboratory test. Data points below a 6-inch drop height were excluded from the analysis since they tended to be caused by small shock events during vibration. The percentage of each impact orientation, including faces, edges, corners, on and around the bottom, on and around the top, vertical faces, and vertical edges, were also calculated. This analyzed data was then used to establish new laboratory test procedures for South Korea.

In addition, the time stamp of each data point was compared with tracking information. This analysis allowed the researchers to determine which delivery stage produced the most impacts. It provided useful information for packaging engineers on what to target to optimize their packages and for courier engineers about which stages need to be improved to reduce their parcel damage rates.

The individual one-way shipments to five destinations were analyzed to calculate drop heights, number of drops, and impact orientations. Table 1 shows various percentiles, the average, and maximum number of drops as a function of the different package sizes and weights used in this current study. It also compares the current study’s results with past studies conducted in Europe and the U.S., and to the ISTA 3A testing standard.

The number of drops observed in the Korean parcel delivery environment was significantly lower than the similar studies conducted in Europe and the U.S., and the ISTA 3A testing standard. This seems to be due to fewer handling points in Korea than in countries with larger territory. Packages in Korea mostly go through only one hub terminal and one sub terminal during any trip. In contrast, packages in Europe and the U.S. have a higher chance of going through more handling points, such as multiple hub and sub terminals, before they get to customers.

It is also important to report the Equivalent Free Fall Drop Height (EFFDH) of Nth highest drop height at 95th percentile level since that is the recommended dataset to utilize when developing a drop test according to ISTA guidelines. The 95th percentile of the highest EFFDH in this study was at least 28% and 17% higher than those in Europe, or recommended by ISTA 3A for testing packages less than 37 kg, respectively. The Korean parcel delivery system also had a higher max EFFDH than most of the other compared regions. This trend indicates that packages shipped in the Korean environment will most likely experience higher shock levels compared to historically investigated regions.

Both the fewer number of drops and the higher EFFDH results prove the uniqueness of the Korean parcel delivery system and show the need to establish their own laboratory testing standards. Therefore, packaging engineers are encouraged to reevaluate their protective packaging designs when the packages are to be shipped through the Korean parcel delivery system. These researchers believe that the current ISTA 3A laboratory testing sequence should be modified to reflect the unique characteristics of the Korean parcel shipping environment.